Precision gears are at the heart of countless mechanical systems, from vehicles to industrial machinery and advanced robotics. Producing high-quality gears efficiently and accurately requires specialized equipment, and horizontal gear hobbing machines have become an essential tool in modern manufacturing. These machines enable the production of gears with exceptional precision, surface finish, and consistency, meeting the demanding standards of today’s industries.

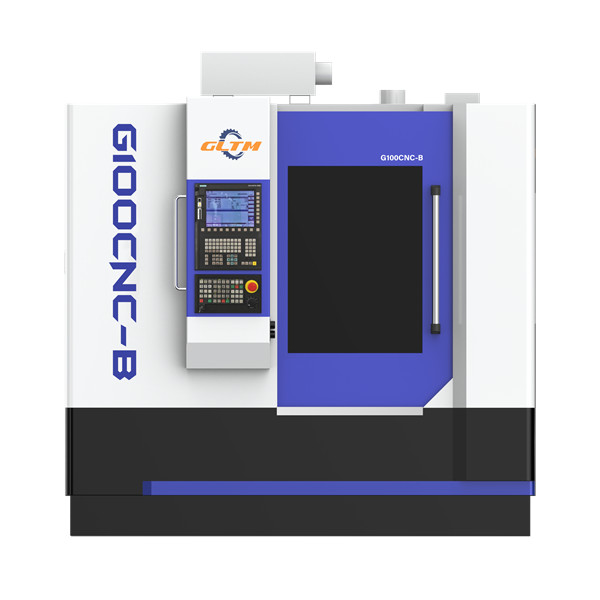

GLT Machinery (GLTM/GLT), a leading Chinese manufacturer of CNC gear hobbing machines, specializes in high-speed, high-efficiency equipment designed for rigidity, reliability, and performance. Their solutions have been successfully applied in automotive, motorcycle, reduction gear, synchronous pulley, pump, and robotics applications, providing clients with tailored gear production solutions. This article explores the key applications of horizontal gear hobbing machines across various industries.

1. Automotive Industry

The automotive sector relies heavily on precise gears for transmissions, differential systems, and engine components. Horizontal gear hobbing machines are particularly advantageous in automotive gear production because they offer:

-

High precision and repeatability: Ensuring consistent gear dimensions for smooth power transmission.

-

High-speed production: Meeting the large-scale demands of automotive manufacturing.

-

Versatility: Capable of producing spur gears, helical gears, and bevel gears used in transmissions and differentials.

GLT Machinery’s CNC horizontal gear hobbing machines deliver reliable performance and high output, enabling automotive suppliers to produce gears that meet stringent quality standards and support fuel-efficient, quiet, and durable vehicles.

2. Industrial Equipment

Industrial machinery—ranging from pumps and compressors to heavy-duty gearboxes—requires durable and precisely machined gears for optimal performance. Horizontal gear hobbing machines provide industrial manufacturers with:

-

Consistent gear quality: Essential for minimizing downtime and maintenance costs.

-

Flexibility: Machines can handle different gear sizes and materials, including hardened steel and alloys.

-

High efficiency: Rapid production without compromising accuracy.

GLT Machinery has equipped numerous industrial gear manufacturers with CNC hobbing machines that ensure robust, reliable gears for applications such as pumps, conveyor systems, and heavy-duty industrial gearboxes.

3. Robotics and Automation

In robotics and automation, gear accuracy is critical. Robots, automated guided vehicles (AGVs), and precision equipment demand:

-

Minimal backlash: For smooth and precise motion control.

-

High surface quality: To reduce wear and extend service life.

-

Compact and lightweight gears: Supporting space-efficient design without sacrificing strength.

Horizontal gear hobbing machines excel in producing small to medium-sized precision gears used in robotic joints, servo motors, and automated systems. GLT Machinery’s CNC machines provide the tight tolerances and high surface finish required for these advanced applications.

4. Advantages of Horizontal Gear Hobbing Machines

Across these industries, horizontal gear hobbing machines offer significant benefits:

-

Rigidity and stability: Ensures high precision even during heavy-duty production.

-

Automation and CNC control: Reduces human error, enhances repeatability, and increases efficiency.

-

Versatility: Supports a wide range of gear types and sizes for multiple applications.

-

Scalability: Ideal for both small batch production and large-scale manufacturing.

GLT Machinery’s focus on high-speed, high-efficiency CNC hobbing machines allows industries to meet tight production schedules while maintaining the quality demanded by modern mechanical systems.

5. Case Study Examples

-

Automotive: Production of helical gears for transmission systems with minimal backlash and high durability.

-

Industrial: Manufacturing bevel and spur gears for pump and compressor assemblies, ensuring long operational life.

-

Robotics: Fabrication of compact precision gears for robotic arms, achieving smooth motion control and accurate positioning.

By using GLT Machinery’s horizontal CNC hobbing solutions, manufacturers in these sectors achieve consistent output, reduced waste, and enhanced operational efficiency.

Conclusion

Horizontal gear hobbing machines are indispensable for industries requiring precision, efficiency, and reliability in gear production. Automotive manufacturers, industrial equipment producers, and robotics developers all benefit from the versatility and high performance of CNC hobbing technology.

GLT Machinery (GLTM/GLT) specializes in high-speed, high-efficiency CNC horizontal gear hobbing machines designed for rigidity, precision, and durability. Their machines have successfully provided gear solutions across automotive, motorcycle, reduction gear, synchronous pulley, pump, and robotics applications, enabling clients to produce high-quality gears that meet demanding industrial standards.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd.