Eco-Friendly Food Packaging Redefined: Explore SCT and IRT by G-COVE

Fluorine-Free and Oil-Resistant Spray Coating Technology (SCT)

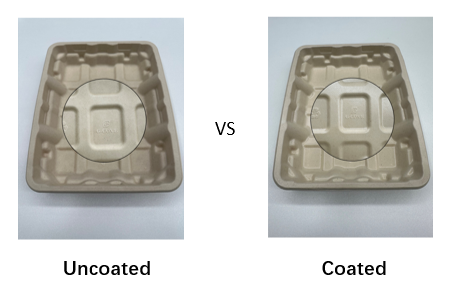

SCT is an innovative and sustainable barrier coating technology that enhances the environmental friendliness of food packaging to further extend the goods shelve life up to 24 months. It replaces traditional PE film on disposable products by uniformly applying water-based coatings to fibers. This ensures 100% biodegradability and recyclability, contributing to a greener planet.

Features of SCT:

-

100% Biodegradable and Recyclable: Fully eco-friendly and sustainable.

-

100% FPAs Free with excellent oil barrier

-

Superior Oxygen barrier (OTR) to protect the goods from oxidize

-

Superior Waterproof and Oil-Resistant Performance: Water Vapor Transmission Rate (WVTR) < 400.

-

Easy Processing: Can be applied using common coating machines with no volatile organic compounds (VOCs).

-

Dual-Sided Application: Non-sticky at room temperature, simple and convenient to form.

-

Food-Contact Safe: All raw materials are compliant with FDA standards.

Quality Assurance with SCT:

-

Frozen Food: Suitable for storage at -18°C and special formulation can up to -60°C

-

Heat Resistance: Compatible with microwaves up to 120°C.

Whether it’s Bowl, Clamshell, Food Compartment Trays, Meat Trays, or other innovative packaging solutions, G-COVE’s products are crafted from natural materials such as bamboo fiber and sugarcane residue. These eco-friendly materials are plastic-free, biodegradable, and designed to meet the diverse demands of modern food packaging.

-

High Adaptability: Our products cover a wide range of packaging applications, including portable meal boxes, frozen food containers, and ready-to-eat meal packaging, catering to the varied needs of the food industry.

-

Technology-Ready Design: G-COVE’s packaging solutions are seamlessly compatible with Modified Atmosphere Packaging (MAP), Vacuum Seal Packaging (VSP), and SCT technologies while maintaining superior eco-friendly performance.

-

Premium Aesthetic Design: Combining functionality with an appealing design, our packaging enhances brand value and attracts consumers.

-

Carbon Footprint Reduction: By replacing traditional plastics packaging with sustainable materials, we contribute to reducing carbon emissions and creating a healthier planet.

G-COVE is not limited to producing Bowl, Clamshell, Food Compartment Trays, Meat Trays; we are actively developing and promoting innovative packaging solutions for various food and industrial applications like inner and outer tray cushion solution for industrial product applications. Our mission is to provide the industry with more flexible and sustainable choices.

Introduction to G-COVE's IRT™ Technology

G-COVE's IRT™ (Intrinsic Resistant Technology) is a groundbreaking innovation focused on sustainability and the application of eco-friendly materials. By incorporating a lipid barrier agent made from starch and protein-based materials directly into the fiber pulp, IRT™ eliminates the need for plastic coatings during the production of molded fiber materials. This revolutionary technology overcomes the limitations of traditional processes, ensuring that products are fully biodegradable while achieving exceptional grease and leak resistance for food packaging.

Thanks to IRT™ technology, G-COVE's products are made with 100% food-safe materials and can remain leak-proof for 2 hours at a high temperature of 80°C. Furthermore, this technology simplifies the manufacturing process by removing secondary coating steps, significantly improving efficiency and environmental performance. With innovation and sustainability at its core, G-COVE provides eco-friendly solutions that meet modern demands. Through IRT™ technology, we are not only advancing the packaging industry but also leading a green revolution focused on environmental stewardship.

Diverse Applications of IRT™ Technology

G-COVE's IRT™ technology is widely applied in various eco-friendly packaging fields, meeting the needs of modern consumers and businesses for sustainable solutions:

1. Foodservice Packaging

IRT™ technology is ideal for single-use food containers such as plates, bowls, and takeaway boxes. These packages offer excellent greaseproof and waterproof performance, maintaining integrity even in high-temperature environments, making them a perfect choice for the foodservice and takeaway industry.

2. Fresh and Cold Chain Packaging

In the transportation and storage of fresh and frozen foods, IRT™ technology ensures leak-proof protection both inside and outside the packaging, preserving product freshness. Fully biodegradable, it meets the strict environmental requirements of the food industry.

3. Fast-Moving Consumer Goods (FMCG) Packaging

IRT™ technology is also suitable for everyday FMCG packaging such as egg cartons, cup carriers, and wine bottle holders. It eliminates the non-biodegradable plastic coating found in traditional packaging, enhancing the environmental value of the products.

4. Agricultural Seedling Containers

Seedling cups and trays made with IRT™ technology remain stable in high-humidity environments and decompose directly after use, turning into organic fertilizer for plants. This makes them widely applicable in agriculture and horticulture.

At G-COVE, we believe that true innovation lies in creating solutions that not only meet the needs of today but also safeguard the future of our planet. With cutting-edge technologies like SCT and IRT™, we are redefining food packaging to be more sustainable, efficient, and adaptable. Join us in our mission to lead the global transition toward eco-friendly packaging and be a part of the movement to build a greener, healthier world for generations to come. Together, we can make a lasting impact—one package at a time.

www.g-cove.com

G-COVE TECHNOLOGY GROUP CO, LTD.