Choosing the right furnace tube cleaning machine is crucial for ensuring the operational efficiency and safety of your facility—especially in high-precision environments like laboratories and semiconductor manufacturing. With the increasing demand for cleanliness and contamination control in thermal processing, investing in the right equipment is not just an option—it’s a necessity.

In this blog post, we’ll explore the key factors to consider when selecting a furnace tube cleaning machine and introduce how Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. can be a strategic partner in helping you achieve optimal performance with customized, high-quality solutions.

1. Understand Your Cleaning Requirements

Start by assessing the specific needs of your operation:

-

Tube material and size: Are your furnace tubes quartz, alumina, or silicon carbide? What are their lengths and diameters?

-

Contaminants: What type of residues or deposits typically accumulate inside your tubes—carbon, metal oxides, organics?

-

Frequency of cleaning: Daily, weekly, or during scheduled shutdowns?

The answers to these questions will influence the level of cleaning power, automation, and precision your equipment must deliver.

2. Prioritize Precision and Safety

In semiconductor and lab environments, even trace contamination can compromise results. Choose a cleaning machine that:

-

Offers non-destructive cleaning to protect delicate tube materials.

-

Uses automated cycles to ensure consistent and repeatable results.

-

Features integrated safety systems for handling chemical agents or thermal cleaning steps.

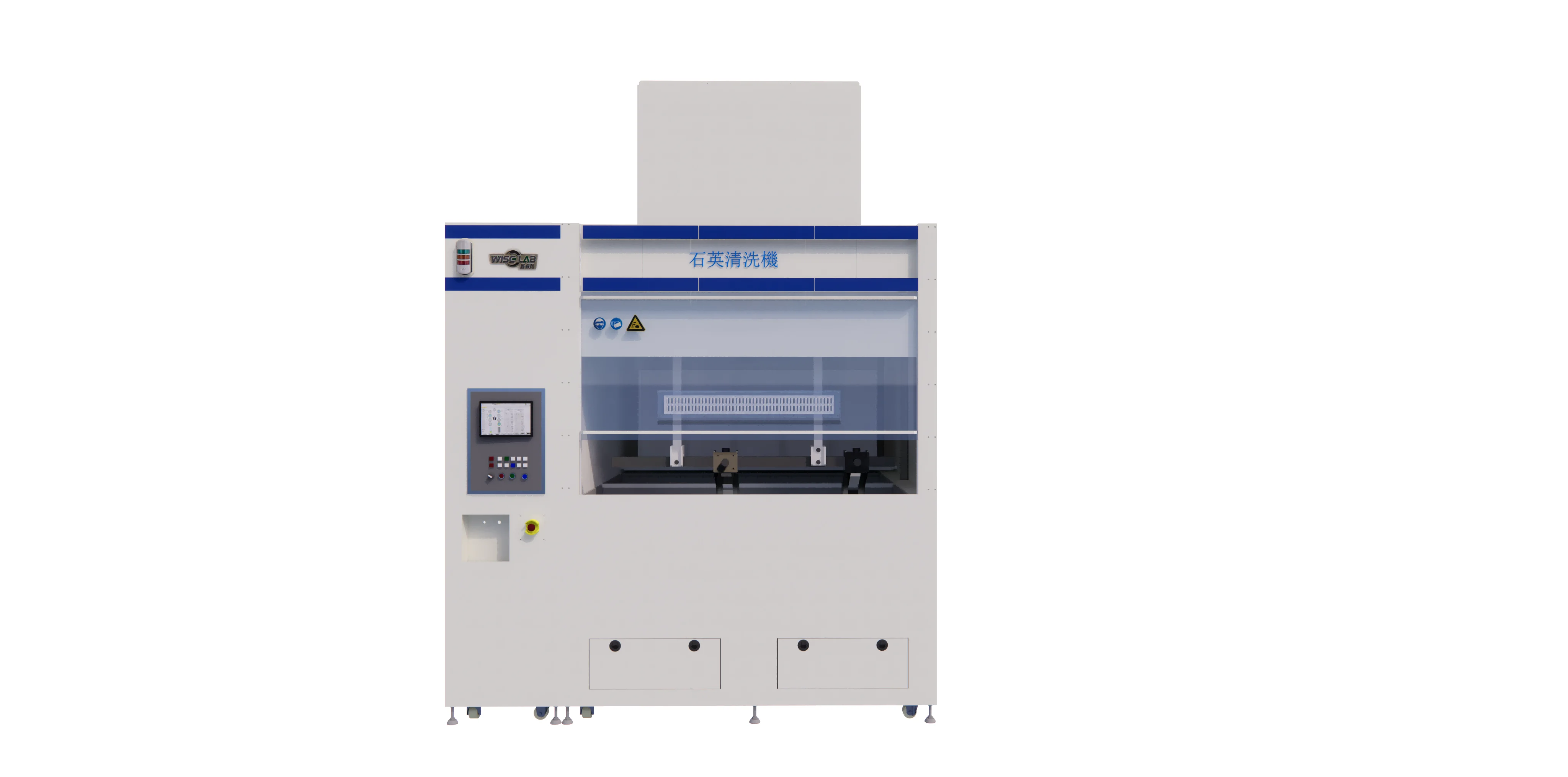

Xinruiwei’s furnace tube cleaning systems are developed with the semiconductor industry in mind. They support ultra-precise operations with configurable options that ensure safe and residue-free cleaning every time.

3. Look for Flexibility and Customization

Every facility is different. A one-size-fits-all solution rarely delivers long-term value. Consider whether the equipment can be:

-

Customized for different tube diameters or materials.

-

Configured with add-ons such as ultrasonic cleaning, vacuum drying, or programmable control interfaces.

-

Adapted to fit within existing process lines or cleanroom protocols.

Xinruiwei excels in providing personalized solutions, from prototype development to full-scale production. Their expertise in plastic-based equipment design ensures chemical compatibility and long service life in harsh environments.

4. Evaluate Quality and Component Standards

A high-quality furnace tube cleaning machine should be built with durable, reliable components. Look for:

-

European-standard parts for pumps, sensors, and valves.

-

Robust construction materials like chemical-resistant plastics or stainless steel.

-

Local manufacturing support for faster service and delivery.

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. manufactures all systems in China using top-grade European components, ensuring both cost efficiency and world-class quality. Their commitment to quality control and delivery reliability sets them apart in the field.

5. Consider After-Sales Support and Service

No matter how advanced your machine is, you’ll need timely technical support to keep it running smoothly. Ask:

-

Is there a responsive local service team?

-

Are spare parts readily available?

-

Can the supplier offer maintenance training or remote diagnostics?

Xinruiwei offers robust after-sales support, including technician training and prompt customer service. With a deep understanding of the needs of semiconductor and laboratory users, they provide peace of mind well beyond the initial purchase.

Conclusion

Choosing the right furnace tube cleaning machine is a strategic decision that impacts productivity, yield, and safety. By focusing on precision, adaptability, and trusted manufacturing partners like Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd., you can ensure your facility operates at the highest standards of cleanliness and efficiency.

Ready to upgrade your furnace tube cleaning process? Partner with Xinruiwei to develop a tailored, high-performance solution built to meet the exacting demands of your industry.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.