X-ray detectors are commonly used to detect foreign matter in food. However, food X-ray machines have far more capabilities than just foreign matter detection. Beyond routine inspections, they can also assess the quantity, contents, and shape of items.

The Vixdetect X-ray detector is equipped with a rich data model that creates a database of product characteristics, enabling fast, high-precision inspection without the need for complex mode selection and parameter tuning. This article briefly introduces the Vixdetect X-ray detector's missing and shape detection capabilities.

1. Functional Introduction

Count Inspection

Automatically detects the number of items in a package (such as biscuits, tablets, capsules, candy, etc.), ensuring that the quantity in each package/box meets the preset value. Suitable for high-speed production lines, it effectively prevents over-packing, under-packing, and missing items, improving production compliance.

Quantity Inspection

Inspects the fill level of liquids, powders, granules, or pastes in packaging (such as beverage bottles, liquid medicines, milk powder, condiments, and cosmetics), ensuring that the volume, height, or weight of the contents meet standards. It can identify gaps caused by underfilling, overfilling, or foam, ensuring that product net content meets standards.

Split Shape Inspection

Identifies microscopic cracks on or within products (such as glass bottles, ceramics, and pharmaceutical tablets). It is suitable for industries with stringent integrity requirements. It can detect microcracks that are difficult to detect with the naked eye, preventing defective products from entering the market and reducing the risk of returns and after-sales service.

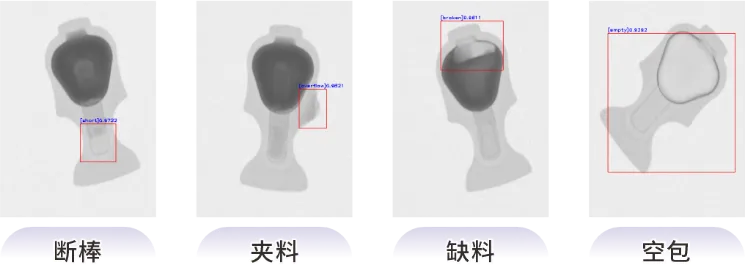

Broken Shape Inspection

Detects physical damage, deformation, or defects in products (such as broken biscuits, cracked snacks, and squeezed packaging). Combined with AI image analysis technology, it distinguishes between flaws and defects. This system is suitable for the food, pharmaceutical, and precision parts industries, ensuring product appearance and functional integrity.

Weight Inspection

The X-ray machine integrates a high-precision weighing module, enabling simultaneous non-destructive weight testing (for products such as canned goods, vacuum-packed foods, frozen products, and pharmaceuticals). This meets the quality control needs of various industries and can detect overweight and underweight issues, effectively helping companies improve product compliance.

2. Practical Application Cases

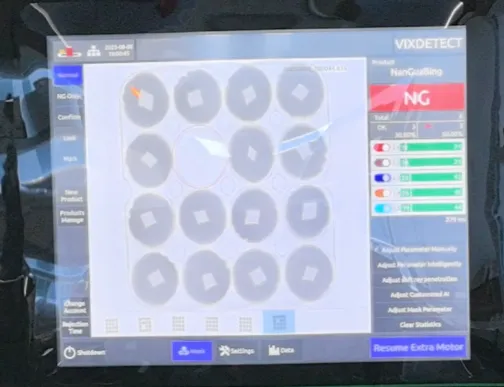

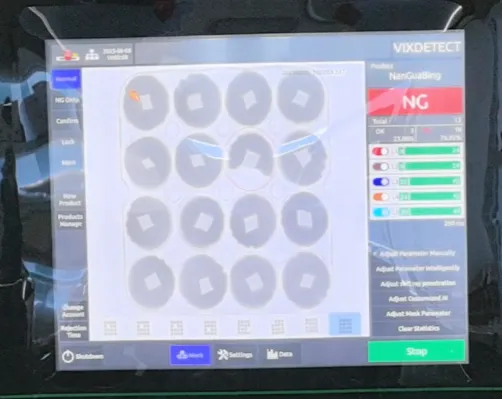

Count Inspection

Case 1. Detecting Missing Quantities in Boxed Biscuits

Case 2. Detecting Missing Drug Instructions

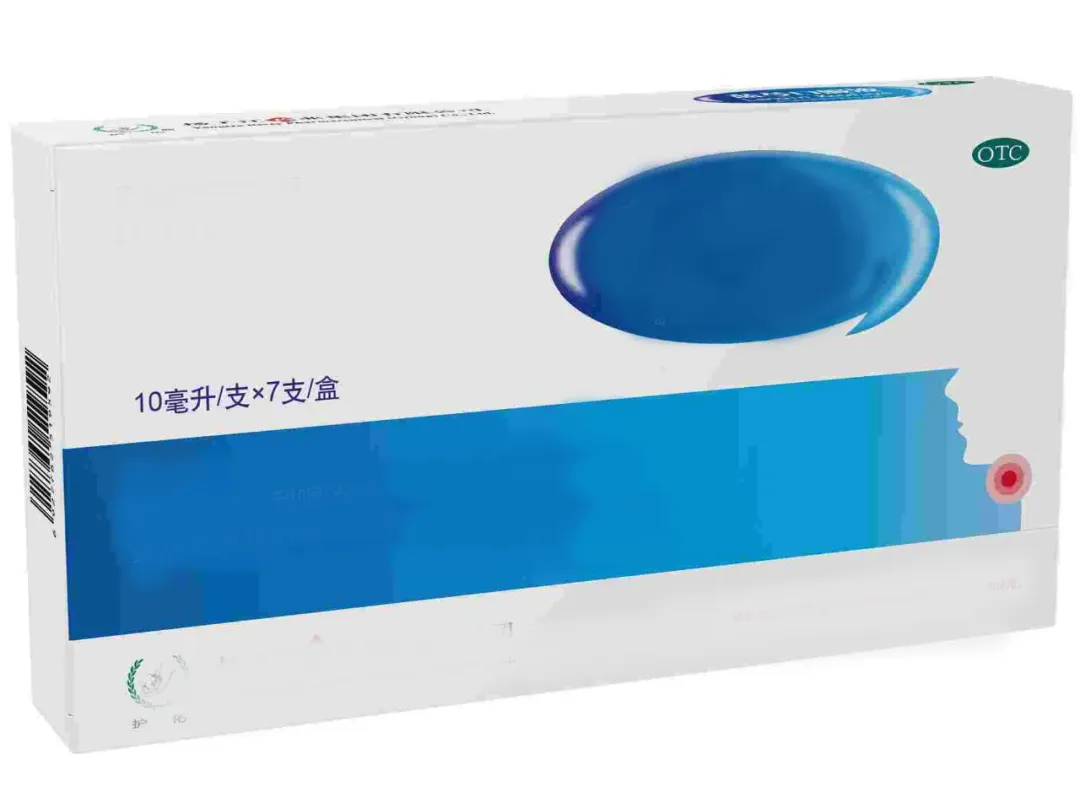

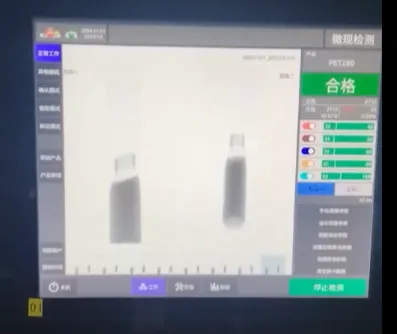

Quantity/Volume Inspection

Case 1. Detecting Liquid Levels in Bottled Milk

Crack Detection (Split Shape Inspection)

Case 1. Detecting Missing and Cracked Tablets

Broken Shape Inspection

Case 1. Detecting Broken Boxed Biscuits

Case 2. Detecting Abnormal Shapes in Cheese Sticks

Weight Inspection

Case 1. Detecting Broken Boxed Biscuits

This article briefly introduces the Vixdetect X-ray machine's capabilities beyond basic foreign body detection, including count inspection, crack inspection, breakage inspection, and weight inspection. It also uses real-world inspection examples to demonstrate the application of each function in real-world inspections. In actual inspections, all of these functions can be combined with the X-ray machine's basic foreign body inspection function for simultaneous inspection. For more customized inspection services, please contact us.

www.vixdetect.net

vixdetect