In today's competitive manufacturing environment, the ability to deliver consistent quality and high efficiency is more critical than ever. Across industries ranging from food and pharmaceuticals to chemicals, plastics, and construction materials, one machine consistently proves itself indispensable: the kneading mixer machine. This equipment is not only designed to handle challenging, viscous, or sticky materials but also engineered to produce homogenous mixtures that directly influence product quality and production outcomes. This article Nantong Kneading Mixing Machine Co., Ltd explores industrial applications of kneading mixer machines.

What Is a Kneading Mixer Machine?

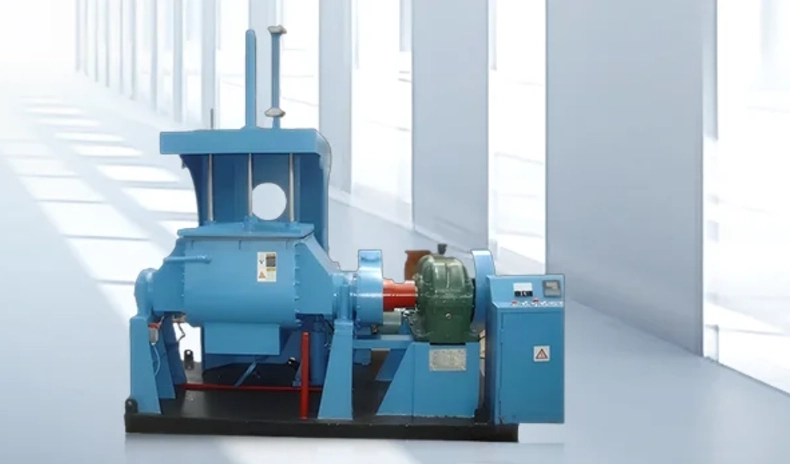

A kneading mixer machine is a heavy-duty industrial mixer designed to combine, knead, and homogenize materials that are too dense, sticky, or viscous for ordinary mixers. Unlike simple blending equipment, these machines are built with strong motors and specialized blades that generate compression, folding, and shear forces. This ensures that even materials with challenging rheological properties achieve uniform consistency.

For example, in dough processing, a kneading mixer ensures that water and flour are thoroughly integrated, eliminating pockets of unmixed flour. In the chemical industry, when mixing resins or adhesives, it prevents clumping and ensures stability of the mixture. The underlying principle is to subject materials to controlled mechanical stress that improves texture, structure, and distribution of ingredients.

Most kneading mixers are equipped with programmable controls that allow fine-tuning of mixing speed, blade rotation, and mixing time. This makes the machine versatile and adaptable across different sectors. Whether used in a bakery, a pharmaceutical plant, or a plastics factory, the kneading mixer machine provides reliability and repeatability that manual labor simply cannot match.

Industrial Applications of Kneading Mixer Machines

The true value of a kneading mixer machine lies in its versatility. It is not confined to one sector but is a universal solution for industries dealing with viscous, high-density, or delicate materials. From dough preparation in bakeries to resin blending in chemical plants, the kneading mixer machine ensures uniformity, consistency, and efficiency. Below are detailed insights into its applications across different industries.

1. Food Industry

In the food industry, the kneading mixer machine is indispensable. Bakeries, confectionery plants, and industrial kitchens depend on it for large-scale production. Mixing by hand or using standard mixers often leads to inconsistencies in gluten development, which directly affects the texture and quality of bread and pastries. A kneading mixer machine applies controlled shear and folding action, ensuring dough elasticity, proper aeration, and uniform hydration.

For confectionery products, such as caramels, fondants, and chocolate fillings, the machine p

revents the separation of sugar, fat, and other ingredients, delivering smooth and stable textures. Large-scale food manufacturers also rely on kneading mixers for producing pasta dough, cookie batters, and even meat-based fillings for dumplings or sausages. By automating these processes, a kneading mixer machine reduces labor costs, increases batch consistency, and ensures compliance with strict food safety standards.

2. Pharmaceutical Industry

In pharmaceuticals, precision is non-negotiable. Every capsule, tablet, or suspension must have an exact balance of active pharmaceutical ingredients (APIs) and excipients. A kneading mixer machine guarantees this uniformity by thoroughly blending powders, binders, and lubricants into a cohesive mass. This prevents the dangerous risk of under-dosing or overdosing in patients.

Vacuum kneading mixers are particularly valuable in pharmaceutical applications. They remove air bubbles during the mixing process, ensuring higher product stability and improved shelf life. This is especially critical in ointments, gels, and creams, where trapped air could affect both efficacy and appearance. By maintaining precise environmental conditions and mixing intensity, the kneading mixer machine upholds the high safety and quality requirements of the pharmaceutical sector.

3. Chemical and Plastics Industry

The chemical and plastics industry deals with highly viscous and complex materials such as rubber, polymers, adhesives, and resins. A standard agitator cannot handle these materials effectively, but a kneading mixer machine applies powerful shear forces that break down particle agglomerates and distribute fillers or additives evenly throughout the mixture.

In rubber compounding, kneading mixers are crucial for dispersing carbon black, silica, and other reinforcing agents. This results in rubber compounds with superior elasticity, durability, and wear resistance. In polymer blending and resin manufacturing, kneading mixers prevent phase separation and improve the homogeneity of thermoplastics, thermosets, and composites. This directly enhances the mechanical and thermal properties of the final product, making the kneading mixer machine a cornerstone of chemical engineering.

4. Construction Materials

Construction industries require reliable and homogenous mixtures to guarantee strength and durability. Ceramic pastes, refractory materials, and cement-based compounds all depend on precise blending. The kneading mixer machine plays a vital role here by ensuring dry powders and liquid additives are thoroughly combined, forming a smooth and uniform mixture.

For example, when producing high-strength refractory bricks or advanced ceramics, uneven distribution of materials can result in weak spots and compromised structural integrity. A kneading mixer machine eliminates this risk by providing consistent shear and kneading action. In cementitious materials, it ensures even hydration and optimal setting times, which are essential for creating durable and crack-resistant structures. Thus, kneading mixers contribute directly to the longevity and safety of buildings and infrastructure.

5. Cosmetics and Personal Care

In cosmetics, appearance and texture are as important as function. Consumers expect creams, gels, and lotions to be smooth, lump-free, and visually appealing. A kneading mixer machine is used to emulsify oils, waxes, and aqueous solutions into stable formulations. It ensures consistency across large batches, preventing phase separation and producing products with uniform viscosity.

For instance, in toothpaste production, a kneading mixer prevents the separation of abrasive particles from the gel base, ensuring the product remains smooth and effective. In creams and body lotions, it blends emulsifiers evenly, producing a silky texture without air bubbles. This not only improves product quality but also enhances consumer confidence in the brand. With rising demand for high-quality personal care products, the kneading mixer machine has become an essential tool for cosmetic manufacturers worldwide.

The kneading mixer machine is far more than a mixer—it is a central piece of equipment that defines efficiency, quality, and consistency in production. By understanding its components, applications, and operational practices, businesses can make informed decisions that directly influence profitability and competitiveness. Whether you are in food processing, pharmaceuticals, chemicals, or construction, choosing the right kneading mixer machine is a strategic move that ensures sustainable growth and customer satisfaction.

https://www.globalkneader.com/Products

www.globalkneader.com

Nantong Kneading Mixing Machine Co., Ltd