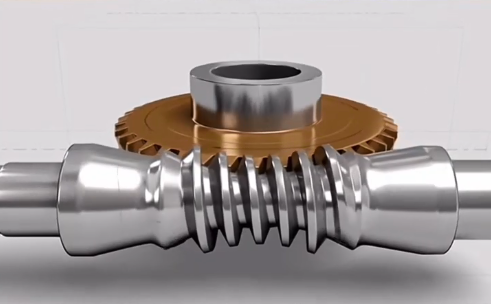

Hourglass worm processing occupies a distinct niche in precision gearing. Unlike simple cylindrical worm gears, hourglass (also called enveloping or globoidal) worms have a variable diameter and tooth profile that “wrap” around the mating wheel. This geometry produces a larger contact area, higher load capacity, and improved transmission efficiency when properly manufactured. Because the hourglass form demands exacting geometry and surface quality, a disciplined processing strategy is essential — one that combines advanced equipment, expert technique, and rigorous quality control. This article outlines the processing essentials and technical advantages of hourglass worm, and why partnering with an experienced supplier such as YOJU yields measurable performance benefits.

What makes hourglass worm processing different

Hourglass worm processing diverges from conventional worm machining on three key fronts: geometry, kinematics, and tolerancing.

-

Geometry: The worm’s cross-section increases from the center toward the ends and the tooth surface is a true enveloping surface rather than a simple helical thread. This requires generating complex spatial profiles instead of repeating identical sections along a cylinder.

-

Kinematics: Cutting and generating motions often require multi-axis coordination (rotary and translational axes with phase relationships) or specialized indexing cutters. Traditional single-axis lathe operations are usually insufficient for final form generation.

-

Tolerancing and finish: Because contact conditions and load distribution depend strongly on micro-geometry and surface finish, the processes must control form error, surface roughness, tooth flank modifications, and lead/pitch deviation to tight limits.

Meeting these demands requires integration of precise equipment, appropriate process planning, and a culture of continual improvement.

Core processing stages and techniques

Hourglass worm processing typically proceeds through a sequence of stages. Each stage contributes to final accuracy and service life.

-

Blank preparation and material control

Begin with raw material qualification, optimized heat treatment, and stress-relieving processes. Material microstructure and hardness uniformity directly affect grindability and wear performance. Strict batch traceability and material inspection mitigate downstream variance. -

Rough turning / pre-machining

Remove bulk material while maintaining concentricity and cylindricity. During this phase the goal is to leave consistent allowances for subsequent generating or grinding operations while avoiding thermal distortion. -

Form generation (milling/generating)

Hourglass worms are commonly generated using specialized form-tools or by multi-axis generating on CNC machines that synchronize spindle and rotary axes. Where available, enveloping tool cutters or shaped hob-like tools produce the correct tooth envelope. For some configurations, a spatial-orthogonal rotary-axis linkage method is used to approximate the enveloping motion. -

Hardening and stabilization

If the design calls for induction or case hardening, maintain dimensional control through fixturing and compensation allowances; post-heat-treatment distortion must be anticipated. Stabilization cycles and controlled tempering reduce residual stresses. -

Finish grinding / honing

Final geometry and surface integrity are achieved by precision grinding or honing. For hourglass worms, profile grinding with specially dressed wheels and synchronized dressing routines ensures accurate lead and pitch and controlled flank geometry. Where surface fatigue life is critical, superfinishing steps lower surface roughness and subsurface work hardening. -

Inspection and validation

Metrology for hourglass worms goes beyond simple tooth-to-tooth checks: coordinate measuring machines (CMM) with nonlinear surface fitting, tooth contact analysis (TCA), and gear metrology systems capable of measuring lead, pitch, profile, and runout across enveloping surfaces are essential. Functional checks—such as backlash under load and efficiency testing in prototype assemblies—confirm that theoretical advantages translate to operational performance.

Precision focus: controlling tooth profile, lead, and pitch

Accurate tooth profile, lead, and pitch are the three most load-bearing geometric parameters for hourglass worm performance:

-

Tooth profile determines the contact pattern and stress distribution. Slight deviations produce concentrated contacts that accelerate wear.

-

Lead (axial helix consistency) governs how uniformly load is shared across the face width; lead error causes edge loading.

-

Pitch controls meshing periodicity; pitch errors introduce vibration and noise.

Advanced equipment — multi-axis CNC generators, precision form tools, and high-quality grinding machines — combined with process recipes that control thermal inputs and machine dynamics, are required to maintain these parameters within narrow tolerances. The downstream benefits are higher transmission efficiency, reduced noise, and prolonged service life.

Expert team and continuous technical evolution

The hourglass worm is not a “set-and-forget” component: optimal processing requires specialists who understand geometry generation, machine kinematics, metallurgical constraints, and inspection science. Experienced engineers and machinists contribute in several ways:

-

Process selection and parameter optimization for the specific material, size, and ratio.

-

Tooling design for custom generating or grinding attachments and fixtures ensuring repeatable setups.

-

Troubleshooting—diagnosing contact anomalies, vibration, or heat-related distortion, and implementing corrective strategies.

-

Adoption of new methods, such as roller-enveloping concepts or double-roller designs, which can reduce friction and enhance efficiency for demanding applications.

An expert team shortens development cycles, reduces scrap, and can tailor hourglass worm processing to unique application requirements.

Custom solutions and application-driven design

One of the principal advantages of hourglass worm gearing is design flexibility. With precise processing, manufacturers can deliver:

-

Custom reduction ratios optimized for motor speed and torque requirements.

-

Face width and helix adaptations to distribute loads for specific radial or axial forces.

-

Material and surface treatments tailored for corrosive environments, high temperatures, or abrasive contaminants.

The processing strategy should be selected with the final environment in mind; for example, marine or mining applications demand robust corrosion protection and abrasion-resistant finishes, while servo-driven automation may prioritize efficiency and low backlash.

Quality assurance and management systems

Delivering reliable hourglass worm components requires a disciplined quality system:

-

Incoming material control (certificates, composition analysis, and hardness checks).

-

Process control plans with documented setup methods, sampling frequencies, and control charts.

-

Traceable inspection records from raw bar to finished part, including serial numbers and batch identifiers.

-

Continuous improvement loops using root-cause analysis and corrective action for nonconformances.

A rigorous management system reduces variation, shortens warranty cycles, and ensures that performance promised at quotation is what arrives on the customer’s assembly line.

Why partner with a specialist for hourglass worm needs

Hourglass worm processing is technically demanding but rewards designers and users with compact, high-capacity, and efficient gearing when executed precisely. Choosing a partner with advanced equipment, an expert team, a track record of custom solutions, and a demonstrable quality system offers several benefits:

-

Predictable performance and reduced integration risk.

-

Optimized lifecycle cost through higher efficiency and longer wear life.

-

Faster time-to-market for bespoke gearsets because development iterations are minimized.

YOJU’s approach—focused on precision tooling, seasoned engineers, tailored solutions, and end-to-end quality control—exemplifies the type of supplier capability that turns hourglass worm potential into operational reality.

Conclusion

Hourglass worm processing is a specialized, high-value activity that bridges advanced machine kinematics, materials engineering, and metrology. When done correctly, it produces gear sets with superior contact characteristics, higher load capacity, and enhanced durability. Success depends on three pillars: precision-focused processes that control tooth profile, lead and pitch; an expert team that can translate application requirements into machining strategy; and a robust quality system that ensures consistency from raw material to finished assembly. For engineers and procurement specialists seeking reliable, high-performance hourglass worm solutions, partnering with a proven specialist is the efficient and low-risk route to realizing the full advantage of this sophisticated gearing form.

www.enyoju.com

YOJU