The aerospace industry demands uncompromising performance, reliability, and compactness in every component it uses. As aircraft and spacecraft become more sophisticated, the electronic systems inside them must adapt to ever-increasing demands for weight reduction, thermal stability, vibration resistance, and signal integrity. This is where rigid flex circuit boards shine. A rigid flex circuit board combines the structural strength of rigid PCBs with the adaptability of flexible circuits. This hybrid structure allows aerospace engineers to design complex 3D assemblies, reduce interconnect failures, and optimize weight and space—all critical factors in aviation and space environments.

SprintPCB offers cutting-edge rigid flex circuit board solutions that are specifically engineered for aerospace-grade applications. By integrating rigid and flexible sections into a single PCB, SprintPCB rigid flex circuit boards eliminate the need for bulky connectors and cabling, simplifying installation and increasing long-term durability.

What Is a Rigid Flex Circuit Board?

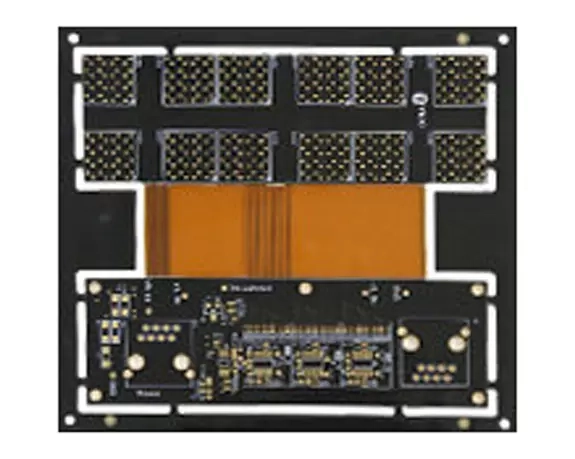

A rigid flex circuit board is a hybrid printed circuit board that seamlessly integrates both rigid and flexible substrates within a single design. This unique combination enables engineers to create compact, lightweight, and highly reliable electronic assemblies that can bend and fold while maintaining structural integrity and electrical performance. The rigid sections provide mechanical stability and support for mounting components, while the flexible sections allow dynamic movement and 3D configuration, making them ideal for applications where space is limited or where vibration and mechanical stress are concerns. Rigid flex circuit boards eliminate the need for bulky connectors and flat cables, resulting in simplified assembly, improved signal integrity, and enhanced durability.

SprintPCB Rigid Flex Circuit Board Solutions for Aerospace Applications

When it comes to aerospace electronics, every gram matters, and every millimeter counts. The complexity of aerospace systems requires electronic solutions that are compact, lightweight, and highly reliable under extreme conditions. SprintPCB rigid flex circuit board solutions are engineered to meet these exact demands, offering superior mechanical strength, signal integrity, and design flexibility.

SprintPCB rigid flex circuit boards leverage advanced lamination, drilling, and imaging technologies to deliver:

Perfect layer alignment – Ensuring signal consistency in mission-critical aerospace systems.

Superior mechanical resilience – Withstanding constant vibration, shock, and thermal cycling.

Dynamic bending capability – Supporting movement in constrained, dynamic 3D assemblies.

Whether used in satellite avionics, fighter jet navigation, or UAV systems, SprintPCB rigid flex circuit boards provide unmatched performance and reliability.

Space-Saving Designs for Confined Aerospace Enclosures

Traditional rigid PCBs often require bulky connectors and flat cables, increasing both the weight and complexity of the system. SprintPCB rigid flex circuit board technology integrates flexible and rigid sections into a single board, allowing multi-plane routing and complex 3D configurations that are ideal for space-constrained aerospace enclosures. In aerospace control modules, for instance, these boards can bend around corners, conform to structural constraints, and reduce electromagnetic interference—resulting in lighter, cleaner, and more efficient electronic assemblies. The flexible tails and rigid sections are optimized to conform without compromising performance or mechanical stability.

Exceptional Vibration Resistance and Harsh-Environment Durability

Aerospace systems are continuously subjected to mechanical stresses such as high-frequency vibrations, accelerations, and shock. Unlike conventional assemblies with fragile connectors and cabling, SprintPCB rigid flex circuit boards minimize interconnects, reducing points of mechanical failure and significantly improving reliability. This makes them especially suited for engine control units and flight control systems, where long-term stability and low maintenance are mission-critical. SprintPCB applies advanced bonding and reinforcement techniques to ensure the boards remain structurally sound under the toughest conditions.

High-Frequency Signal Integrity for Avionics and Satellites

In aerospace communication and navigation systems, signal loss is not an option. SprintPCB rigid flex circuit boards are engineered for excellent signal integrity, featuring low impedance paths and tightly controlled multilayer stack-ups. This is particularly beneficial in high-frequency applications such as radar, GPS, and telemetry systems. Thanks to precise imaging and registration processes, each conductive layer is perfectly aligned to maintain performance consistency across a wide frequency range—even in extreme temperatures and altitudes.

Simplified Assembly and Reduced Lifecycle Costs

By integrating rigid and flexible sections, SprintPCB rigid flex circuit boards eliminate the need for separate connectors and ribbon cables. This not only reduces weight and component count but also simplifies the overall assembly process. The result is faster production times, streamlined certification, and reduced risk of error during installation.

For aerospace OEMs, this translates to lower lifecycle costs, fewer maintenance interventions, and improved system diagnostics. SprintPCB supports customers from prototype design to volume production, ensuring each solution is tailored for performance, manufacturability, and compliance.

Proven Across Aerospace and Other High-Reliability Sectors

While designed with aerospace in mind, SprintPCB's rigid flex circuit board technology is also trusted in:

Medical implants, where flexibility and long-term reliability are critical.

High-end wearables, which require dynamic flexibility and compact form factors.

Automotive electronics, particularly in EVs and autonomous vehicle systems.

However, aerospace remains the most demanding application—and SprintPCB meets that challenge head-on. With ISO-certified facilities and extensive engineering expertise, SprintPCB delivers flight-ready rigid flex circuit boards that set new standards in reliability and performance.

From Concept to Launch—Full-Cycle Support

SprintPCB provides comprehensive support throughout the product lifecycle. Whether you're developing a first-of-its-kind aerospace module or scaling to production, our team ensures flawless execution from start to finish. We work closely with OEMs and integrators to optimize material selection, stack-up design, thermal behavior, and mechanical stress resistance.

With rapid prototyping and high-mix, low-volume capabilities, SprintPCB rigid flex circuit boards empower aerospace innovators to bring bold ideas to life—faster, safer, and with total confidence.

As aerospace systems grow increasingly complex, the need for compact, durable, and high-performance electronic solutions has never been greater. SprintPCB rigid flex circuit boards rise to this challenge by delivering unmatched mechanical reliability, electrical integrity, and design versatility in one integrated solution.

From prototyping to mass production, SprintPCB supports your innovation every step of the way. Whether you're developing avionics for commercial aircraft, control systems for satellites, or mission-critical modules for UAVs, our rigid flex circuit board technology ensures you never have to compromise between performance and space. Partner with SprintPCB to streamline your design, enhance reliability, and accelerate time-to-market in even the most demanding aerospace applications.

https://www.sprintpcb.net/pcb/Rigid-Flex-PCB.html

www.sprintpcb.net

SprintPCB