In industries where flammable gases, vapors, dust, or combustible liquids are present, safety is not optional—it is fundamental. From oil and gas facilities to chemical plants and hazardous manufacturing zones, every component within the system must meet strict safety standards. Among these components, explosion-proof pipe fittings play a critical role in protecting equipment, workers, and production continuity.

What Are Explosion-Proof Pipe Fittings?

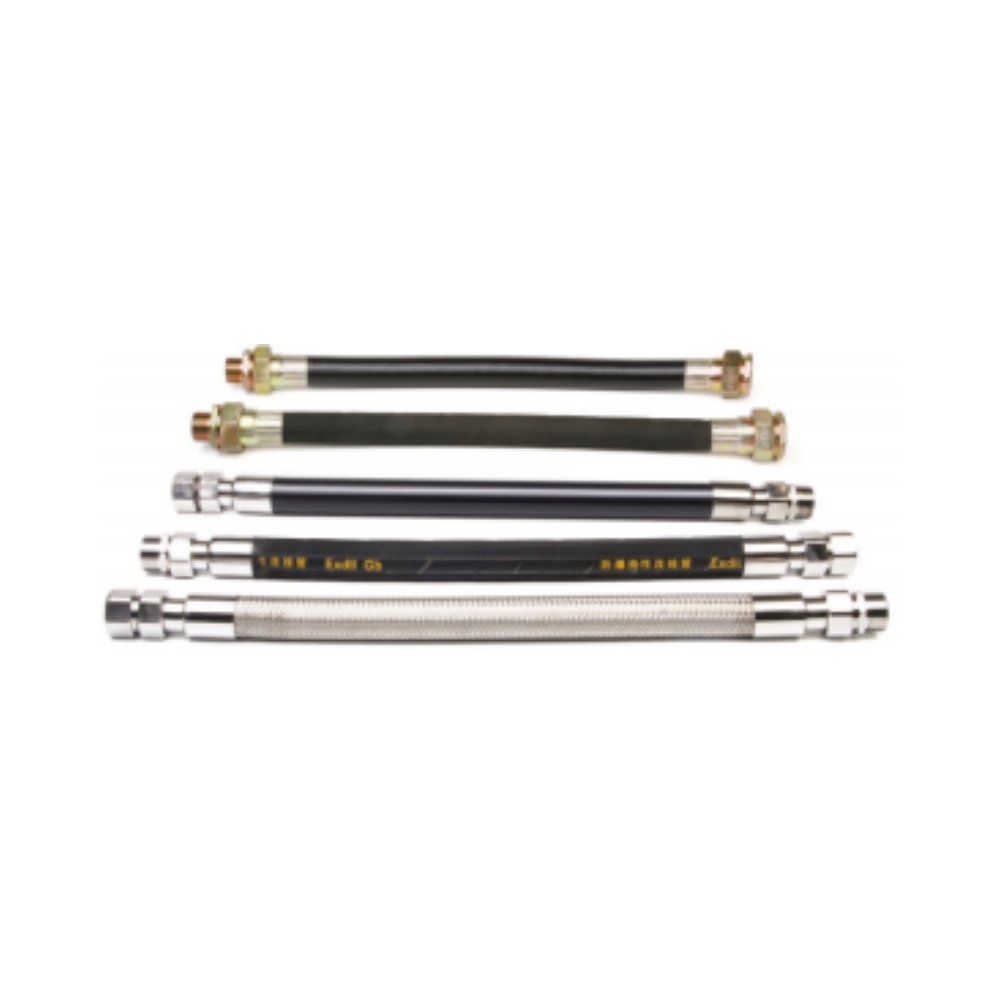

Explosion-proof pipe fittings are specialized connectors designed to safely transmit fluids, gases, or cables in environments where explosions may occur. Their primary function is to prevent sparks, heat, or pressure from escaping the system and igniting surrounding hazardous substances.

Unlike ordinary pipe fittings, explosion-proof designs must comply with international standards such as ATEX, IECEx, NEC, or GB, depending on the region and application. These fittings are commonly used in conjunction with explosion-proof enclosures, lighting systems, motors, and instrumentation.

A typical example is the explosion-proof flexible connecting pipe, which allows controlled movement and vibration absorption while maintaining a sealed, flame-resistant pathway. A detailed reference can be found in this specialized product solution for explosion-proof flexible connecting pipes, widely used in hazardous environments.

High-Strength Materials for Extreme Conditions

One of the most important features of explosion-proof pipe fittings is material selection. These fittings must endure harsh conditions such as high pressure, corrosive chemicals, extreme temperatures, and mechanical stress.

Common materials include:

-

Stainless steel (304 / 316) for corrosion resistance

-

Carbon steel with anti-corrosion coatings

-

Aluminum alloys for lightweight explosion-proof applications

Material quality directly affects service life and safety performance. Inferior materials may crack under pressure or corrode over time, increasing the risk of leaks or ignition. Reliable manufacturers like Xinliming focus on controlled material sourcing and precision machining to ensure consistency across all fittings.

Precision Threading and Sealing Design

In hazardous environments, even microscopic gaps can pose serious risks. Explosion-proof pipe fittings feature precision-threaded connections and multi-layer sealing structures to prevent leakage of flammable substances.

Key sealing features include:

-

Tapered threads with tight tolerance control

-

Flame-path design to cool and contain ignition sources

-

High-performance sealing rings resistant to oil, heat, and chemicals

This level of design ensures that, even in the event of internal ignition, the flame or pressure will not propagate outside the fitting.

Resistance to Vibration and Mechanical Stress

Industrial environments often involve heavy machinery, pumps, compressors, and moving equipment. Vibration is unavoidable and can loosen standard pipe fittings over time. Explosion-proof pipe fittings are designed to withstand continuous vibration without compromising structural integrity.

Flexible explosion-proof connecting pipes are especially valuable in these scenarios. They absorb movement and mechanical shock while maintaining a sealed connection between fixed and moving components. This reduces stress on rigid piping systems and helps extend overall system lifespan.

Compliance with Hazardous Area Certifications

A defining feature of explosion-proof pipe fittings is compliance with recognized safety standards. Certification ensures that the product has been tested under simulated explosion conditions and meets regulatory requirements.

Common certification considerations include:

-

Flameproof enclosure performance

-

Pressure resistance

-

Temperature classification

-

Impact and corrosion resistance

Using certified explosion-proof fittings is often mandatory in hazardous zones such as Zone 1, Zone 2, Class I Division 1, or Class I Division 2 areas. Choosing uncertified products can lead to regulatory violations and serious safety risks.

Applications Across Multiple Industries

Explosion-proof pipe fittings are widely used in industries where safety and reliability are critical:

-

Oil and gas exploration and refining

-

Chemical and petrochemical plants

-

Pharmaceutical manufacturing

-

Coal mining and processing

-

Paint, coating, and solvent facilities

-

Hazardous material storage and transfer systems

In many of these applications, explosion-proof fittings are integrated with explosion-proof lighting, control panels, and electrical systems to form a complete safety solution.

Ease of Installation and Maintenance

While safety is the top priority, practical considerations such as installation and maintenance also matter. Well-designed explosion-proof pipe fittings allow for straightforward installation using standard tools, reducing downtime during system setup or upgrades.

Features that support ease of use include:

-

Standardized thread sizes

-

Modular design for flexible system layouts

-

Durable finishes that reduce maintenance frequency

A well-manufactured fitting minimizes the need for frequent replacement, lowering long-term operational risk and maintenance effort.

Why Manufacturer Expertise Matters

Not all explosion-proof pipe fittings are created equal. The experience and technical capability of the manufacturer directly influence product reliability. Xinliming focuses on explosion-proof solutions with strict quality control, ensuring that every fitting meets performance expectations for hazardous environments.

From material inspection to final testing, professional manufacturers understand that a single weak point can compromise an entire system. This is why choosing a specialized explosion-proof pipe fitting supplier is a critical decision for industrial buyers.

Conclusion

Explosion-proof pipe fittings are a foundational element of safety in hazardous environments. Their strength, sealing performance, vibration resistance, and certification compliance make them indispensable in industries where explosions pose real risks.

By understanding the key features that define high-quality explosion-proof pipe fittings, engineers and procurement professionals can make informed decisions that protect people, equipment, and operations. When safety standards are non-negotiable, investing in proven explosion-proof solutions is not just a requirement—it is a responsibility.

www.xlmexplosionprooflight.com

Xinliming