As an important industrial automation equipment, the drive valve interlock system is widely used in many fields such as petroleum, chemical industry, electricity, natural gas, etc. It has the function of ensuring the safety of equipment operation and preventing operation errors. The drive valve interlock system greatly improves operation efficiency and safety by intelligently controlling and protecting the start and stop, operation sequence, valve action, etc. of the equipment. However, with the extension of the use time, the wear and aging of the equipment are inevitable, which requires regular maintenance and inspection of the drive valve interlock system. This article will discuss in detail and provide operators with practical maintenance guidelines.

1. Drive valve interlock function

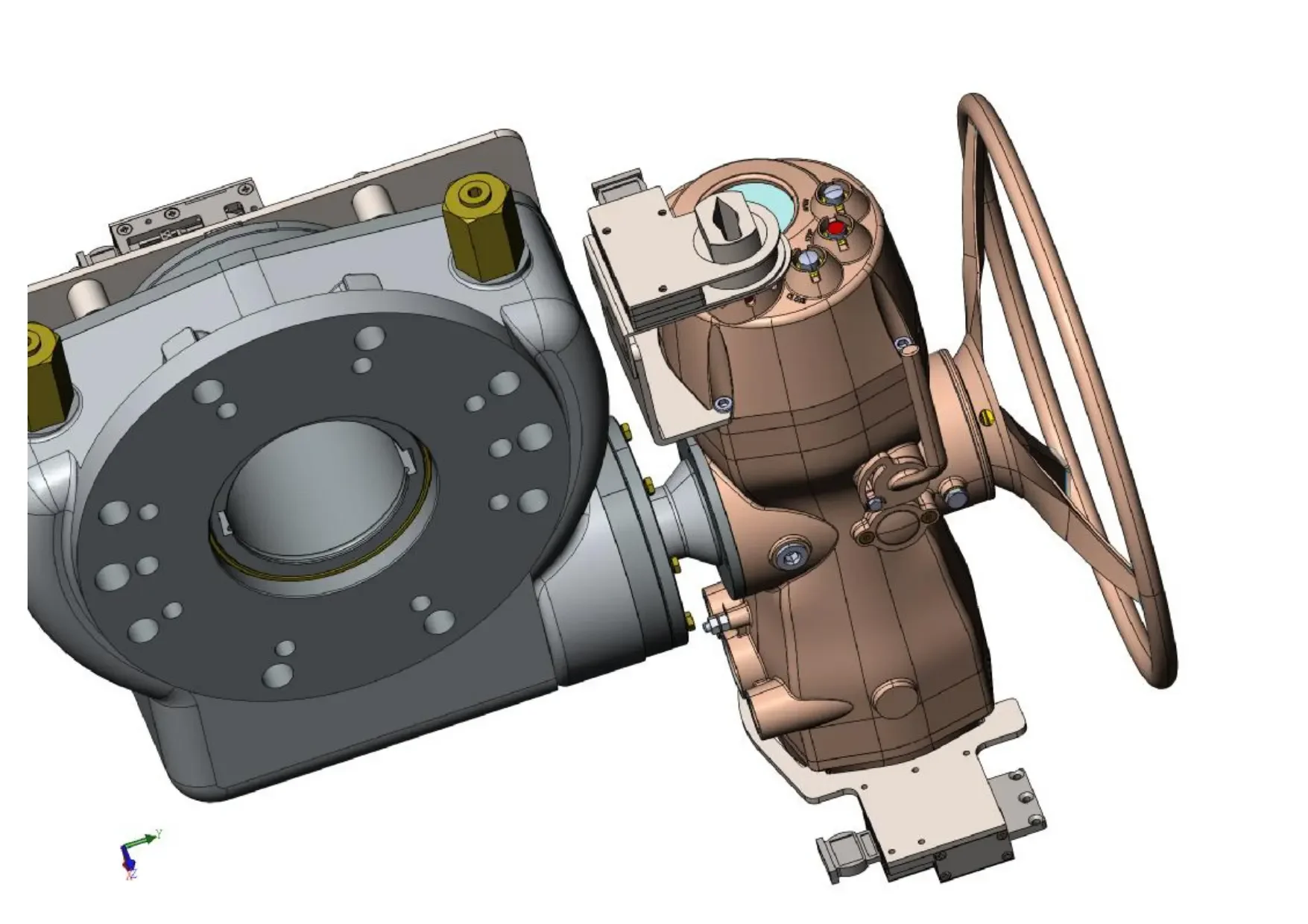

The drive valve interlock system, referred to as the valve interlock system, has the main function of using a series of logical controls and mechanical linkage to make the valve open and close only in the set order and method to prevent equipment damage or safety accidents caused by operation errors.

The main functions of the drive valve interlock system include:

Preventing misoperation: By setting the correct start and stop sequence, equipment damage or safety hazards caused by improper valve operation can be avoided.

Protecting equipment: When equipment failure or abnormal conditions occur, the interlock system can respond in time to protect key equipment.

Improve the level of automation: Through automated control and operation, reduce the impact of human factors on equipment safety and improve the stability and reliability of the system.

2. Maintenance Guide

The maintenance of the drive valve interlock system is not only related to the normal operation of the equipment but also directly affects the safety and production efficiency of the production process. Therefore, the maintenance work should follow the following principles:

Regular inspection: The components of the drive valve interlock system need to be inspected regularly, including valves, drivers, interlock devices, and control circuits. Regular inspections can detect potential problems in time and prevent equipment failures.

Pay attention to equipment cleaning: The cleaning of the drive valve interlock system is an important part of maintenance. Pollutants, dust, and corrosive substances can affect the operating efficiency of the equipment and even cause equipment damage. Therefore, regularly clean the impurities outside and inside the equipment to keep the equipment clean and in good working condition.

Prevent overload and damage: During maintenance, special attention should be paid to the load of valves and drivers. Long-term overload operations may cause system damage, and unnecessary overload operations should be avoided during maintenance.

Lubrication and replacement of wearing parts: Some mechanical parts (such as valves and drivers) in the drive valve interlock system need to be refueled or lubricated regularly. Lubricating oil can reduce friction and improve the working efficiency of components. In addition, it is necessary to check the worn parts regularly and replace the damaged parts in time.

Calibration and testing: The control system of the drive valve interlock system should be calibrated regularly to ensure that its control logic is correct and responsive. During the test, the actual operating environment can be simulated to check whether the valve opening and closing conform to the predetermined logic, and ensure that the response of the interlock device meets the requirements.

The maintenance of the drive valve interlock system is the key to ensuring the long-term and stable operation of industrial automation equipment. Through regular inspection, cleaning, lubrication and testing, system failures can be effectively prevented and the service life of the equipment can be extended.

As a drive valve interlock distributor, we not only provide high-quality equipment but also are committed to providing customers with comprehensive after-sales service and technical support. Our products meet international standards and are widely used in petroleum, chemical, power, and other industries to ensure the safe and stable operation of various types of equipment. We provide customers with regular maintenance services to ensure that the interlock system is always in the best working condition in actual production. We insist on providing professional solutions to ensure that customers can fully enjoy an efficient and safe automation operation experience.

www.nudango.com

Shanghai Nudango Safety Equipment Co., Ltd.