In today's world, where climate unpredictability is on the rise, ensuring the safety of both personnel and infrastructure against the dangers of lightning strikes is more crucial than ever. As a leading innovation in this field, the Sunlightweld lightning warning system has positioned itself as a game-changer. By integrating cutting-edge IoT sensors and real-time data transmission, this system offers a robust solution for lightning detection and monitoring, empowering users to stay ahead of severe weather events. Moreover, the seamless connection to platforms for continuous monitoring and data storage ensures that users benefit from real-time alerts, system reliability, and data-driven insights, making it an indispensable tool for many industries.

Why Sunlightweld Lightning Warning System Stands Out

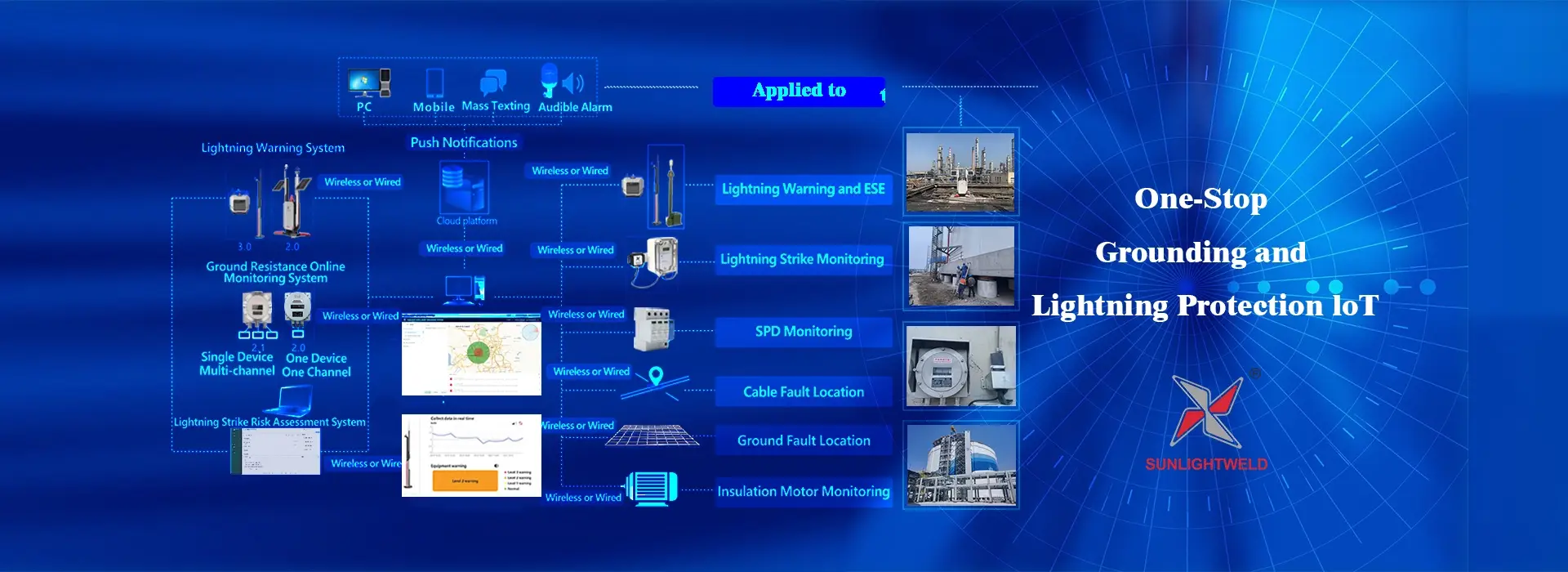

The Sunlightweld lightning warning system is not just another warning system; it is a step into the future of smart technology. At the heart of this system lies its ability to connect to a central platform that leverages the power of the Internet of Things (IoT). This connection enables continuous monitoring of grounding networks, lightning activity, and system status, which is essential for ensuring the safety and reliability of the infrastructure it protects.

One of the standout features of the Sunlightweld lightning warning system is its real-time data transmission capabilities. These sensors collect live data, which is immediately transmitted to a central platform. This is crucial for industries that rely on instantaneous information to make quick decisions and mitigate potential damage. Furthermore, the integration of these systems allows for easy data storage, making it a perfect solution for future research and long-term tracking of lightning activity and system performance.

What truly differentiates the Sunlightweld system from other competitors is the system's digitalization aspect. Unlike traditional lightning warning systems that only offer alerts in isolated events, the Sunlightweld LWS offers a full suite of digital tools that make managing lightning threats more systematic and reliable. From seamless integration with platforms to easy data storage and detailed insights, Sunlightweld has pioneered the intelligent, connected systems that represent the future of lightning protection.

This digitization isn't just a trend, it's a game-changer that brings unparalleled benefits to businesses and infrastructure. By allowing the system to be connected to a central platform, companies can continuously monitor and control their lightning safety measures with ease. This is just one way that Sunlightweld is ahead of its competitors, helping clients stay safe and more profitable.

Sunlightweld Lightning Warning System Installation Guideline

While the Sunlightweld lightning warning system offers exceptional performance and advanced technology, it is important to ensure proper installation to maximize its efficiency and effectiveness. Correct installation of the system plays a crucial role in preventing system malfunction or unnecessary disruptions. Below are the essential guidelines for installing the Sunlightweld lightning warning system.

Avoid Hazardous Areas

Smoke or Smoke-Producing Objects

It is essential that the system be installed away from sources of smoke or items that can produce smoke. This includes nearby industrial processes or smoke-producing machines that can impact sensor accuracy. Smoke particles can cause interference with the sensors, which may lead to false data or incorrect system readings. Ensuring that the system is installed in a smoke-free environment guarantees more accurate monitoring and fewer disruptions.

High-Voltage Lines

Sunlightweld lightning warning system should never be installed under or near high-voltage lines. These power lines emit strong electromagnetic fields, which can distort the sensor readings or cause the system to malfunction. High-voltage proximity can increase the risk of electromagnetic interference (EMI), potentially hindering the system's lightning detection capabilities. Avoiding these areas will ensure the reliability of the system.

Metal Structures

Installing the Sunlightweld lightning warning system near metal structures such as steel poles, fences, or communication towers should be avoided. Metal can influence the electric and magnetic fields that the sensors detect, distorting the readings and potentially leading to false alerts. This can result in unnecessary downtime or maintenance. Therefore, installing the system in areas with minimal metal infrastructure is crucial to ensuring optimal performance.

Dense Trees or Vegetation

Vegetation, particularly large trees, can have an impact on lightning detection, especially if the trees are in close proximity to the installation site. Trees can interfere with the electromagnetic fields the system detects, leading to inaccuracies. It's important to install the system away from these elements to avoid these potential issues.

HVAC and Cooling Units

Another important consideration is the installation of the system in close proximity to HVAC ducts, cooling towers, or ventilation systems. These units may emit vibrations, noise, or heat, which could interfere with the system's sensors. As a result, it's crucial to avoid placing Sunlightweld lightning warning system near these structures to ensure smooth operation and accurate lightning detection.

Installation Steps for Sunlightweld Lightning Warning System

The installation process for the Sunlightweld lightning warning system should be approached systematically to ensure optimal performance. Below are the detailed steps for installing lightning warning system:

Confirm Installation Location

Upon delivery of the equipment to the final site, the technical team must visit the location to confirm the installation site. It is essential to verify that power, network access, and IP ports are suitable for installation. These preliminary checks are important to avoid delays in the installation process and ensure that the system will operate as expected.

Acceptance Check

After the Sunlightweld lightning warning system arrives, an acceptance test is performed. The team checks the order list, tools, and packaging to ensure everything is intact and there is no damage to the equipment. This step is vital to ensuring that the system components are fully functional before installation begins.

Transport to Site

Once the acceptance test is complete, Sunlightweld lightning warning system is transported to the designated installation site. The transportation process must be carefully managed to prevent damage during transit.

Concrete Base Preparation

On-site construction begins with pouring concrete for the foundation (120cm×150cm, thickness: 15-20cm). This is a critical step to ensure that the system remains stable and secure once it is in place. The base must be properly leveled and the correct dimensions followed to ensure a solid foundation for the system.

Embedded Screws and Conduits

The pre-embedded items, such as four M12×15 screws, ensure that the Sunlightweld lightning warning system is tightly secured. The conduit material can be customized according to the customer's preference, either PVC or galvanized. Properly securing the system prevents potential movement or damage during extreme weather events.

Base Curing

The concrete foundation must be cured for 7-15 days. During this time, the foundation must be watered three times per day to ensure its strength and integrity. A properly cured base guarantees the stability and durability of the entire system.

System Commissioning

After the curing process, Sunlightweld lightning warning system is connected, and system commissioning begins. Following the system's installation, the technical team will refer to manuals such as Firmware Burning Instructions-JFas-v1.0.0, Platform New Device Operation Procedure, and System Software Interface Function Description for proper setup. This step ensures that the system is configured correctly and is ready for use.

Training

After system commissioning, the team will provide on-site training to staff. This includes an overview of the system's functionality and an explanation of how to operate it correctly. Proper training ensures that the team is ready to use the system efficiently and take full advantage of its features.

Final Acceptance

A final acceptance test is performed, where clients, contractors, and supervisors ensure that the system works as intended. The test results are compiled into an acceptance report and customer satisfaction survey. This final step ensures that everything is in working order and meets the client's expectations.

Sunlightweld's Competitive Advantage: The Power of China's Supply Chain

Sunlightweld excels in delivering cutting-edge technology with superior manufacturing efficiency, thanks to China's advanced industrial capabilities. This ensures high-quality products at competitive prices, offering clients up to 30% higher profit margins than competitors. Focused on global expansion, Sunlightweld actively seeks partnerships to create long-term relationships and expand market reach, providing exceptional solutions and support.

The Sunlightweld lightning warning system stands as a leader in the industry, offering superior technology and innovative solutions that are truly transforming lightning detection and safety. By seamlessly integrating IoT sensors, real-time data transmission, and platform connectivity, Sunlightweld ensures that businesses are equipped with the most reliable and advanced lightning warning technology available. From meticulous installation guidelines to superior product advantages, Sunlightweld provides a comprehensive solution that not only safeguards infrastructure but also contributes to better long-term decision-making through data storage and research capabilities. As the company expands globally, its commitment to reliability, innovation, and customer satisfaction ensures that Sunlightweld will remain at the forefront of the lightning warning system industry for years to come.

https://www.sltup.com/Lightning-Protection-System

www.sltup.com

Sunlightweld