Mechanical joint fittings play a pivotal role in various industries, providing a reliable and efficient means of connecting pipes and components. From plumbing systems to industrial applications, these fittings ensure secure and leak-free connections. In this comprehensive guide, we will delve into the intricacies of mechanical joint fittings, exploring their types, applications, installation methods, and advantages.

- Understanding Mechanical Joint Fittings:

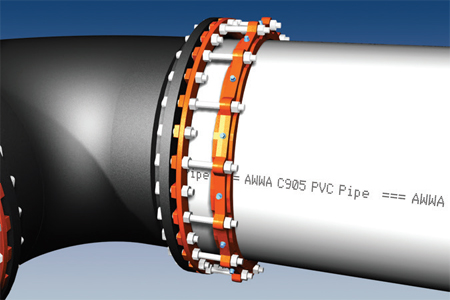

Mechanical joint fittings are specialized components designed to connect pipes, valves, and other equipment in a mechanical manner. Unlike traditional welding or soldering methods, these fittings rely on mechanical force to create a tight and durable joint. They consist of two main components: the spigot and the gland. The spigot is the male end of the fitting, while the gland is the female end that houses a rubber gasket. - Types of Mechanical Joint Fittings:

There are several types of mechanical joint fittings, each tailored to specific applications. These include:

a) Mechanical Joint Couplings: These fittings are used to connect two pipes of the same diameter, providing a flexible and adjustable joint. They are commonly used in plumbing systems and water distribution networks.

b) Mechanical Joint Adapters: These fittings allow for the transition between different pipe materials or sizes. They ensure a secure connection while accommodating variations in pipe dimensions.

c) Mechanical Joint Tees and Elbows: These fittings enable the branching or changing of direction in a pipeline. They are crucial in complex plumbing systems and industrial piping networks.

- Applications of Mechanical Joint Fittings:

Mechanical joint fittings find extensive use in various industries, including:

a) Water and Wastewater Management: In municipal water supply systems and wastewater treatment plants, mechanical joint fittings are employed to connect pipes, valves, and hydrants. Their robustness and leak-free performance ensure the integrity of the system.

b) Industrial Piping: Mechanical joint fittings are widely utilized in industrial settings, such as chemical plants, refineries, and manufacturing facilities. They facilitate the efficient flow of fluids and gases, withstanding high pressures and temperatures.

c) Fire Protection Systems: Fire sprinkler systems heavily rely on mechanical joint fittings to connect the pipes and sprinkler heads. These fittings ensure quick and reliable water distribution during fire emergencies.

- Installation Methods:

Proper installation is crucial for the optimal performance of mechanical joint fittings. The process involves the following steps:

a) Preparation: Clean and inspect the pipe ends, ensuring they are free from debris, rust, or damage. Check the gasket for any defects.

b) Lubrication: Apply a suitable lubricant to the gasket and the spigot to ease the assembly process and ensure a watertight seal.

c) Assembly: Insert the spigot into the gland, ensuring proper alignment. Use mechanical force, such as a wrench or a hydraulic tool, to tighten the joint securely.

d) Testing: Conduct a pressure test to verify the integrity of the joint and ensure there are no leaks.

- Advantages of Mechanical Joint Fittings:

Mechanical joint fittings offer several advantages over other joining methods:

a) Flexibility and Adjustability: These fittings allow for slight misalignments and angular deflections, accommodating variations in pipe positioning.

b) Easy Maintenance and Repairs: Mechanical joint fittings can be disassembled and reassembled without damaging the pipes, making maintenance and repairs more convenient.

c) Cost-Effectiveness: Compared to welding or soldering, mechanical joint fittings require less specialized equipment and labor, resulting in cost savings.

Conclusion:

Mechanical joint fittings are indispensable components in various industries, providing secure and durable connections for pipes and equipment. Understanding their types, applications, installation methods, and advantages is crucial for professionals and enthusiasts alike. By harnessing the power of mechanical joint fittings, industries can ensure efficient fluid and gas transportation while minimizing the risk of leaks and failures. Embrace the reliability and versatility of mechanical joint fittings in your next project, and experience their transformative impact firsthand.