In the manufacturing industry, efficiency and precision define success. Among the many advancements that have transformed production processes, solid face mask making machines stand out as a remarkable example of automation and innovation. These machines streamline the entire mask production process — from material feeding and folding to welding and cutting — ensuring consistency, hygiene, and speed.

Broadfair Automation Equipment Co., Ltd., a high-tech enterprise integrating research and development, production, and sales, has become a leading name in the automation equipment industry. The company is recognized for its commitment to advanced technology, high-quality standards, and customized automation solutions that meet the demands of modern manufacturing.

Understanding the Role of Solid Face Mask Making Machines

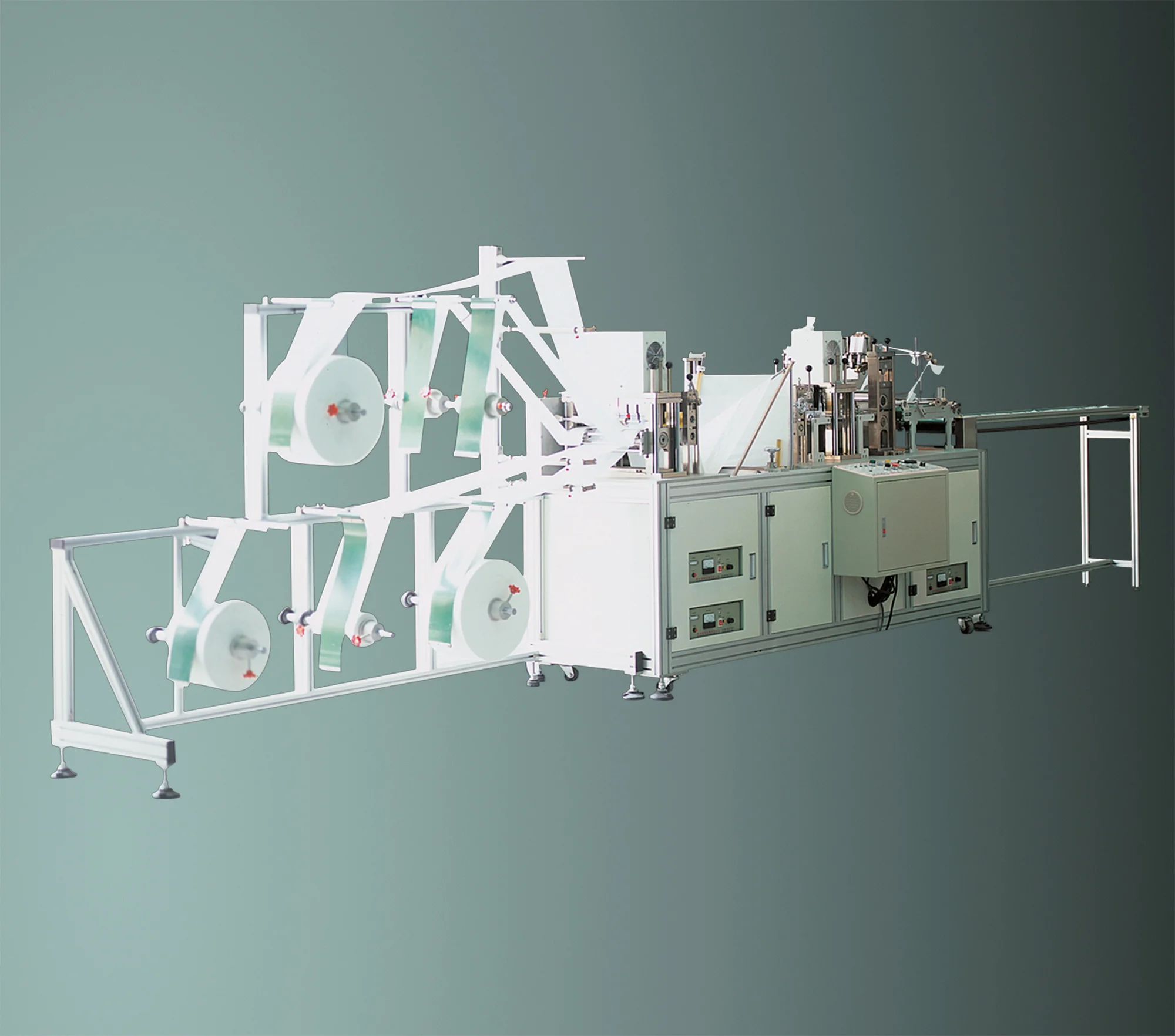

Solid face mask making machines are fully automated systems designed to produce masks with precise shape and structure. Unlike manual or semi-automatic methods, these machines ensure uniform quality and high output while reducing labor costs.

The process typically involves automatic feeding of nonwoven fabrics, ultrasonic welding for strong and clean seams, and accurate cutting to maintain the mask’s design and fit. The automation not only enhances efficiency but also guarantees product safety and compliance with hygiene standards — crucial factors in the healthcare and protective equipment industries.

From Concept to Design: Preparing for Production

Before production begins, design and planning are essential. Manufacturers must define the type, size, and specifications of the mask to ensure that the machine’s configuration matches their needs. The design phase includes:

Material selection: Choosing high-quality nonwoven fabrics that meet filtration and comfort standards.

Machine configuration: Adjusting settings for ear loop attachment, nose clip placement, and folding style.

Quality parameters: Setting production tolerances, thickness levels, and output rates.

At Broadfair Automation Equipment Co., Ltd., engineers collaborate closely with clients to optimize each machine according to their design goals and production requirements.

The Production Process Using Solid Face Mask Making Machines

Once setup is complete, the production process flows seamlessly. The machine integrates several key stages that ensure continuous and accurate output:

Material feeding and layering: The base fabrics are automatically fed into the machine and layered according to mask specifications.

Ultrasonic welding: High-frequency ultrasonic waves fuse the layers without the need for adhesives, ensuring strong and hygienic bonds.

Nose clip and ear loop application: Automated systems insert and secure components precisely for comfort and durability.

Cutting and shaping: Precision cutters define the final mask shape, minimizing material waste.

Quality inspection and counting: The machine can include automatic detection systems to remove defective pieces and tally the finished products.

This streamlined process enhances productivity while maintaining uniform quality across every piece.

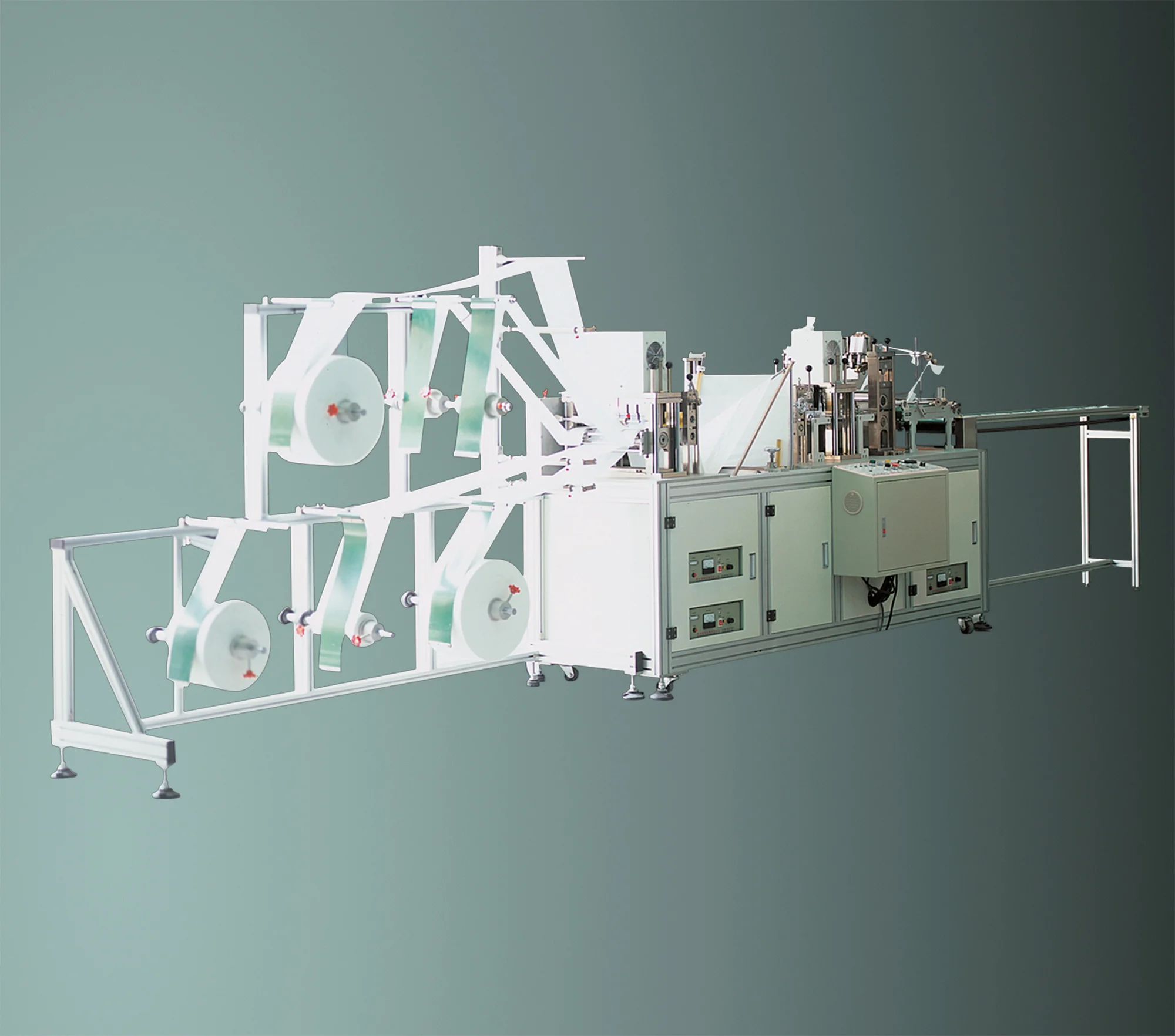

Advantages of Using Automated Mask Making Equipment

Solid face mask making machines deliver several benefits that make them indispensable in modern production environments:

High efficiency: Continuous operation with minimal downtime boosts output capacity.

Consistent quality: Automation eliminates human error and ensures uniform results.

Cost savings: Reduced labor dependency lowers overall production costs.

Clean and safe manufacturing: Contact-free processes improve hygiene and reduce contamination risks.

Flexible operation: Machines can be adjusted to produce different mask styles or sizes as needed.

These advantages help manufacturers stay competitive in a demanding and quality-driven market.

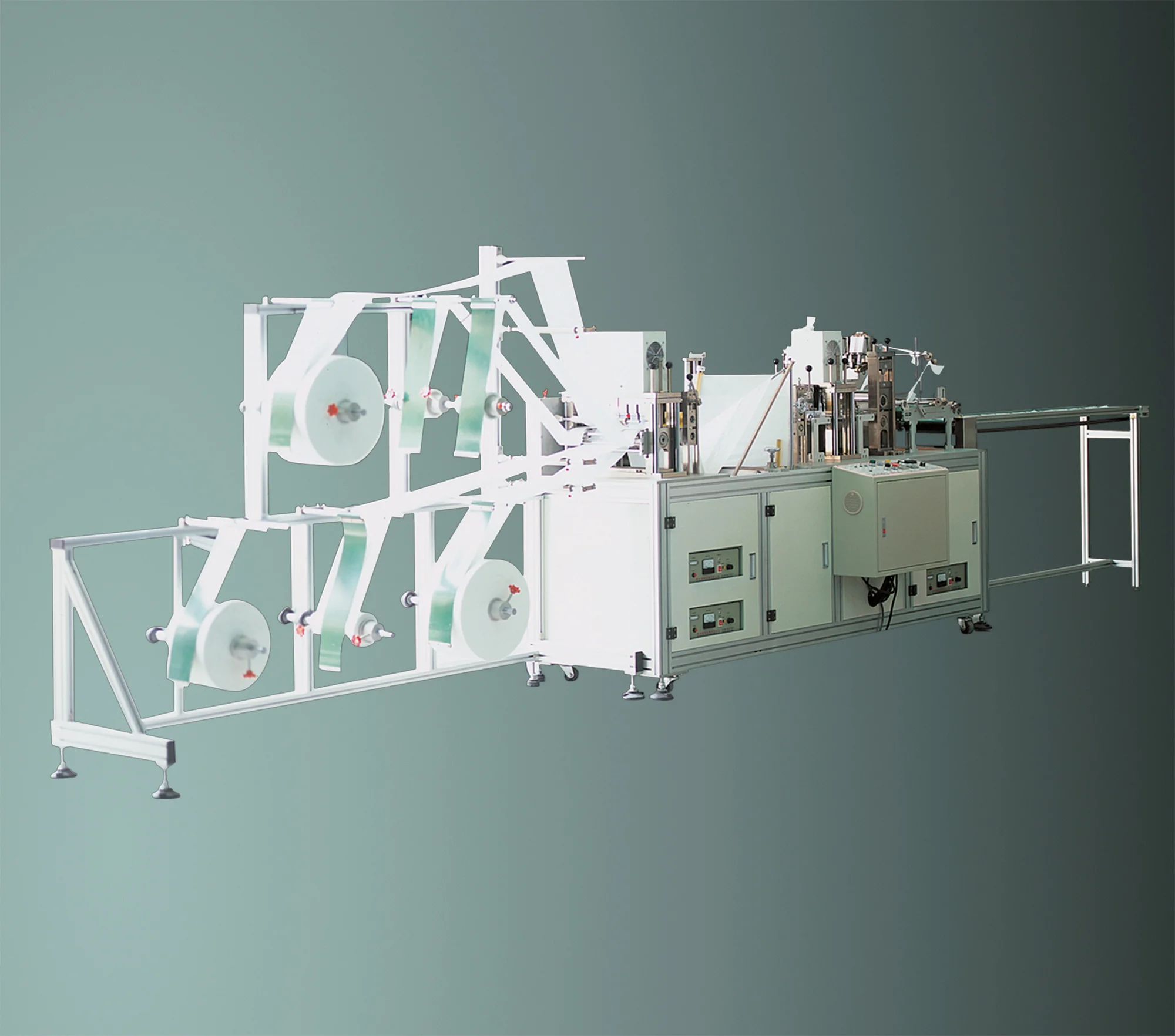

Maintenance and Quality Control

Regular maintenance is vital for maximizing the performance of solid face mask making machines. Routine cleaning, lubrication, and inspection of ultrasonic components help prevent breakdowns and maintain production stability.

At Broadfair Automation Equipment Co., Ltd., every machine is designed with user-friendly maintenance systems and high-quality parts to ensure long service life and reliable performance. The company also provides professional technical support and training to help operators achieve optimal results.

Frequently Asked Questions

Q: What materials can solid face mask making machines process?

A: They typically handle various nonwoven fabrics such as melt-blown, spunbond, and composite materials used in medical or industrial masks.

Q: How does ultrasonic welding improve mask quality?

A: Ultrasonic welding creates clean, precise seams without glue, resulting in strong bonds and improved filtration efficiency.

Q: Why choose Broadfair Automation Equipment Co., Ltd.?

A: The company combines advanced R&D, precision manufacturing, and excellent after-sales service, delivering efficient, reliable, and customizable automation solutions for mask production and beyond.

Conclusion

Solid face mask making machines represent the perfect balance between innovation, quality, and productivity. By integrating advanced automation with precision engineering, they allow manufacturers to achieve high efficiency while maintaining strict hygiene and safety standards.

With the expertise of Broadfair Automation Equipment Co., Ltd., businesses gain access to cutting-edge technology, robust equipment, and dedicated technical support. From design to production, Broadfair’s machines empower manufacturers to produce premium-quality masks with consistency, reliability, and confidence.

In today’s competitive manufacturing landscape, choosing the right automation partner makes all the difference — and Broadfair Automation Equipment Co., Ltd. continues to stand out as a trusted leader in delivering excellence at every stage of production.

Top Industrial Uses of Solid Face Mask Making Machines in Healthcare and Manufacturing

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.