In the world of industrial heating and pressing, Hot Platen plays a crucial role in ensuring uniform temperature distribution and efficient heat transfer. These specialized plates are widely used in various industries, including woodworking, composite material manufacturing, and rubber molding. In this guide, we will explore the key features, benefits, and applications of Hot Platen, helping you make an informed decision for your industrial needs.

What is a Hot Platen?

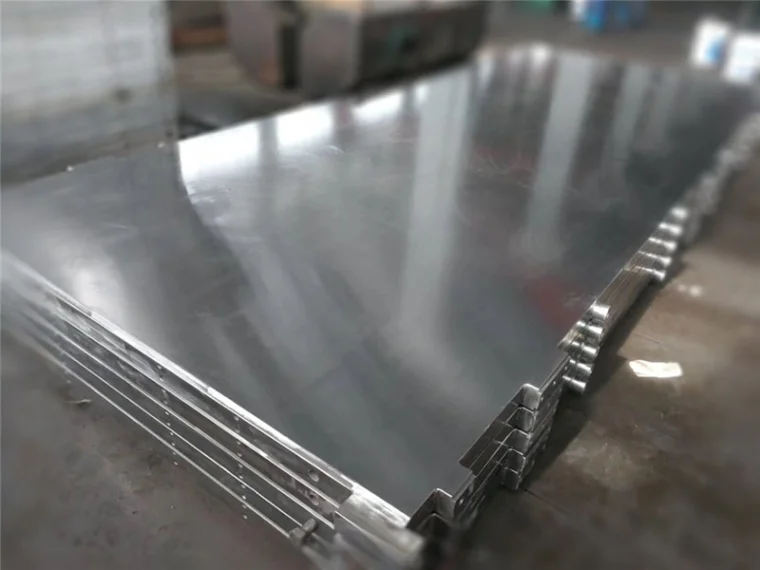

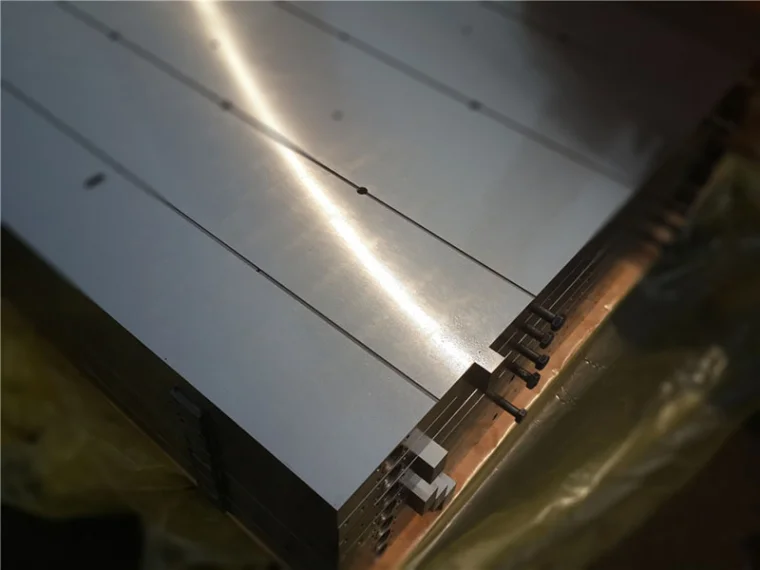

A Hot Platen, also known as a thermal conductive steel platen, is a heating plate used in hydraulic presses, laminating machines, and industrial heat transfer systems. It is designed to provide consistent and controlled heating to improve the production efficiency and quality of the final product.

Key Features of Hot Platen

1. High Thermal Conductivity: Manufactured using premium steel materials, ensuring even heat distribution across the surface.

2. Durability & Corrosion Resistance: Engineered to withstand high temperatures and extreme pressure, prolonging its lifespan.

3. Customizable Sizes & Designs: Available in various dimensions, thicknesses, and surface finishes to meet industry-specific requirements.

4. Precision Temperature Control: Integrated with advanced heating elements to maintain stable and uniform temperature levels.

Applications of Hot Platen

Hot Platens are extensively used in multiple industries for different processing needs, including:

1. Woodworking & Veneer Pressing – Used in hot press machines for plywood, MDF, and laminates manufacturing.

2. Composite Material Processing – Ideal for producing carbon fiber, fiberglass, and other advanced materials.

3. Rubber & Plastic Molding – Ensures precise heat control for molding rubber components and plastic sheets.

4. Textile & Laminating Industries – Used for fabric and decorative lamination processes.

How to Choose the Right Hot Platen for Your Industry?

When selecting a Hot Platen, consider the following factors:

1. Material & Heat Conductivity – Ensure the platen is made from high-quality steel or aluminum for optimal performance.

2. Size & Thickness – Choose the appropriate dimensions based on the press machine specifications.

3. Temperature Range & Control System – Select a platen with an adjustable temperature control system to match your processing needs.

4. Surface Finish & Treatment – Look for hardened or coated surfaces to prevent wear and corrosion.

Why Choose LIANKUN Hot Platen?

At LIANKUN, we specialize in manufacturing high-performance Hot Platens that deliver superior heat transfer, durability, and efficiency. Our products undergo rigorous quality control to ensure reliability in demanding industrial applications. Whether you need a standard or customized solution, our team is committed to providing the best Hot Platen solutions tailored to your requirements.

Conclusion

A high-quality Hot Platen is essential for improving production efficiency, material quality, and overall operational performance. By choosing LIANKUN’s premium hot press platens, you can ensure consistent and reliable heating for your industrial processes.

Looking for the best Hot Platen for your business? Explore our range of high-performance heating plates at LIANKUN Hot Platen or contact us today for a customized solution!

E-mail:ivy@nuknail.com

E-mail:eco@nuknail.com

Precision Milled Pressure Plate: Custom Solutions for Your Manufacturing Needs

www.nuknail.com

Kunshan Liankun Hotplaten Co., Ltd.