When selecting materials for high-temperature, high-pressure, or corrosive environments, engineers and industrial buyers often face a critical decision: nickel-based alloys or stainless steel. Both material families are widely used across aerospace, energy, and chemical industries, yet their performance limits differ significantly when operating conditions become extreme.

This article provides a practical comparison between nickel-based alloys and stainless steel, explaining where each material excels, where limitations appear, and how to make informed material choices for demanding applications.

Understanding the Material Foundations

Stainless Steel: Iron-Based with Added Protection

Stainless steel is primarily an iron-based alloy containing chromium, and often nickel and molybdenum. Chromium forms a passive oxide layer on the surface, which provides corrosion resistance in many environments. Austenitic stainless steels, such as 304 and 316, are widely used because of their balance of strength, corrosion resistance, and cost efficiency.

However, stainless steel’s performance is ultimately limited by its iron base, especially under sustained high temperatures or in highly aggressive chemical environments.

Nickel-Based Alloys: Engineered for Extremes

Nickel-based alloys are fundamentally different. Nickel is the primary base element, not just an additive. Their superior properties are achieved through the precise addition of chromium (Cr), molybdenum (Mo), iron (Fe), titanium (Ti), and other alloying elements.

This design allows nickel-based alloys to maintain mechanical strength, corrosion resistance, and microstructural stability in environments that would quickly degrade conventional steels, including stainless steel.

Performance Comparison in Extreme Environments

High-Temperature Strength

One of the most critical differences between nickel-based alloys and stainless steel appears at elevated temperatures.

Stainless steel generally performs well up to moderate temperatures. Beyond certain limits, it begins to lose strength, suffers from creep deformation, and experiences oxidation or carburization.

Nickel-based alloys, such as Inconel 718, Inconel 625, and Incoloy 800H, are specifically designed to retain strength at high temperatures over long periods. This makes them indispensable in applications like gas turbines, furnace components, and high-temperature heat exchangers.

Verdict: Nickel-based alloys clearly outperform stainless steel in sustained high-temperature environments.

Corrosion Resistance in Aggressive Media

Stainless steel offers good corrosion resistance in mild to moderately corrosive environments. However, it can struggle with:

Pitting and crevice corrosion in chloride-rich environments

Stress corrosion cracking under certain conditions

Rapid degradation in strong acids and reducing chemicals

Nickel-based alloys, particularly Hastelloy C-22, Hastelloy B-3, and Monel 400, are engineered to resist both oxidizing and reducing environments. They perform reliably in chemical processing systems, offshore platforms, and acid-handling equipment.

Verdict: For severe chemical exposure, nickel-based alloys offer a much wider safety margin.

Thermal Stability and Long-Term Reliability

In extreme environments, material degradation often occurs gradually rather than through sudden failure. Microstructural stability over time is critical.

Stainless steel may experience grain growth, embrittlement, or phase changes after prolonged high-temperature exposure.

Nickel-based alloys maintain stable microstructures even after extended service, which is why they are preferred in aerospace engines, power generation equipment, and petrochemical plants where shutdowns are costly.

Verdict: Nickel-based alloys provide superior long-term reliability under thermal stress.

Mechanical Strength and Fatigue Resistance

While stainless steel provides adequate strength for many applications, its fatigue resistance decreases under cyclic thermal and mechanical loads.

Nickel-based alloys, especially precipitation-hardened grades like Inconel 718 and Haynes 282, are designed to withstand repeated stress cycles without cracking or deformation.

Verdict: Nickel-based alloys perform better in fatigue-critical applications.

Typical Application Scenarios

Where Stainless Steel Is Often Sufficient

Stainless steel remains a practical and efficient solution for:

Food and beverage processing equipment

Water treatment systems

Architectural and structural components

Moderate-temperature piping and tanks

In these environments, operating conditions do not exceed the performance envelope of stainless steel.

Where Nickel-Based Alloys Are Essential

Nickel-based alloys become necessary when failure is not an option, such as in:

Aerospace engines and exhaust systems

Chemical reactors handling strong acids

High-temperature furnace components

Oil and gas equipment exposed to sour environments

Power plant boilers and superheaters

In these cases, stainless steel may meet initial requirements but fail prematurely in long-term service.

Overview of Available Nickel-Based Alloy Families

Nickel-based alloys cover a wide range of engineered materials, including:

Incoloy (e.g., 800, 800H, 800HT, 825, 903, 907) for high-temperature and oxidation resistance

Inconel (e.g., 600, 625, 718, 725, 740H, 783) for extreme temperature and mechanical stress

Monel (e.g., 400, K-500) for marine and alkaline environments

Hastelloy (e.g., C-22, B-2, B-3, G series) for severe chemical corrosion

Haynes alloys for advanced aerospace and turbine applications

Precision alloys (e.g., 4J29, 4J36) for controlled expansion and dimensional stability

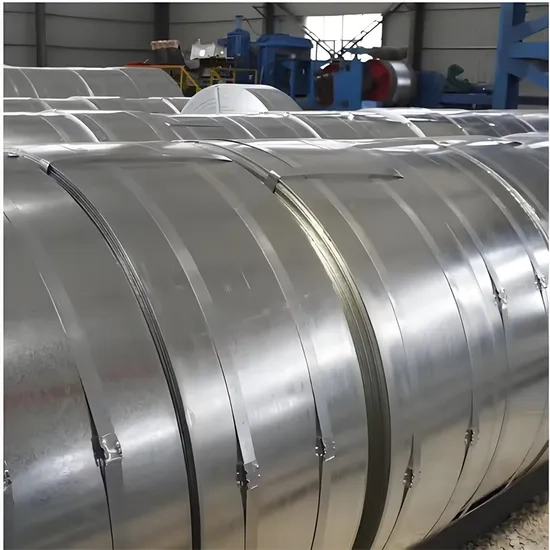

These alloys are available from stock in multiple product forms, including plate, sheet, coil, seamless and welded tube/pipe, round bar, flat bar, hex bar, and custom profiles.

A full overview of available grades and product forms can be found at

Nickel-based alloy products.

How to Choose Between Nickel-Based Alloys and Stainless Steel

For engineers and procurement teams, the decision should be based on operating conditions rather than material familiarity. Key factors include:

Maximum and continuous operating temperature

Type and concentration of corrosive media

Mechanical load and fatigue requirements

Expected service life and maintenance access

In many cases, stainless steel may appear adequate on paper, but nickel-based alloys provide a higher margin of safety and longer service life in extreme environments.

Conclusion

Stainless steel remains a versatile and cost-effective material for a wide range of industrial applications. However, when operating conditions involve extreme heat, aggressive corrosion, or long-term mechanical stress, nickel-based alloys consistently outperform stainless steel.

By understanding the strengths and limitations of each material family, engineers and industrial buyers can make informed decisions that balance performance, reliability, and operational risk.

www.xingxuanalloys.com

Xingxuan trading Co., Ltd.