Dynamic sealing applications demand reliability, durability, and precision. From rotary shafts to reciprocating pistons, equipment in automotive, industrial, and energy sectors relies heavily on seals that can withstand high pressure, vibration, temperature fluctuations, and continuous motion. Rubber X-rings, particularly when combined with metal bonding, have become the preferred choice for extending seal life and maintaining leak-proof performance in these challenging environments.

Rubber X-rings, or quad rings, feature a four-lobed cross-section that creates multiple sealing surfaces. Compared with traditional O-rings, this design reduces friction, prevents twisting and rolling, and enhances lubrication retention. When the rubber is vulcanized or chemically bonded to a metal insert, such as stainless steel, carbon steel, or aluminum, the resulting metal bonded rubber seal combines flexibility with structural strength, offering long-term reliability even under extreme operating conditions.

This article explores how rubber X-rings perform in dynamic sealing environments, discusses material selection, design considerations, and highlights the key industries benefiting from these high-precision seals.

Why Seal Life Matters in Dynamic Applications

Dynamic seals face unique challenges not found in static applications. Motion generates friction, heat, and material fatigue, which can lead to premature wear and leakage. Common failure modes include:

l Rolling or twisting of the seal in reciprocating applications

l Extrusion under high pressure

l Thermal degradation in fluctuating temperature environments

l Abrasion from contact with rough or improperly finished surfaces

By addressing these challenges through proper seal design, material selection, and manufacturing precision, engineers can significantly extend the life of seals, reduce maintenance, and improve system reliability. Rubber X-rings, especially metal bonded designs, are engineered to meet these stringent requirements.

Material Options for Extended Durability

The performance of X-rings depends heavily on the rubber compound used. Different elastomers provide unique advantages in dynamic sealing:

l NBR (Nitrile Rubber): Resistant to oils, fuels, and hydraulic fluids; suitable for automotive and industrial hydraulic systems.

l EPDM: Excellent resistance to water, steam, and weathering; commonly used in HVAC and water-handling applications.

l Silicone: Maintains flexibility across a wide temperature range, ideal for low mechanical stress but thermally challenging environments.

l FKM (Fluorocarbon): High chemical resistance and temperature stability; suitable for aggressive fluids and high-temperature machinery.

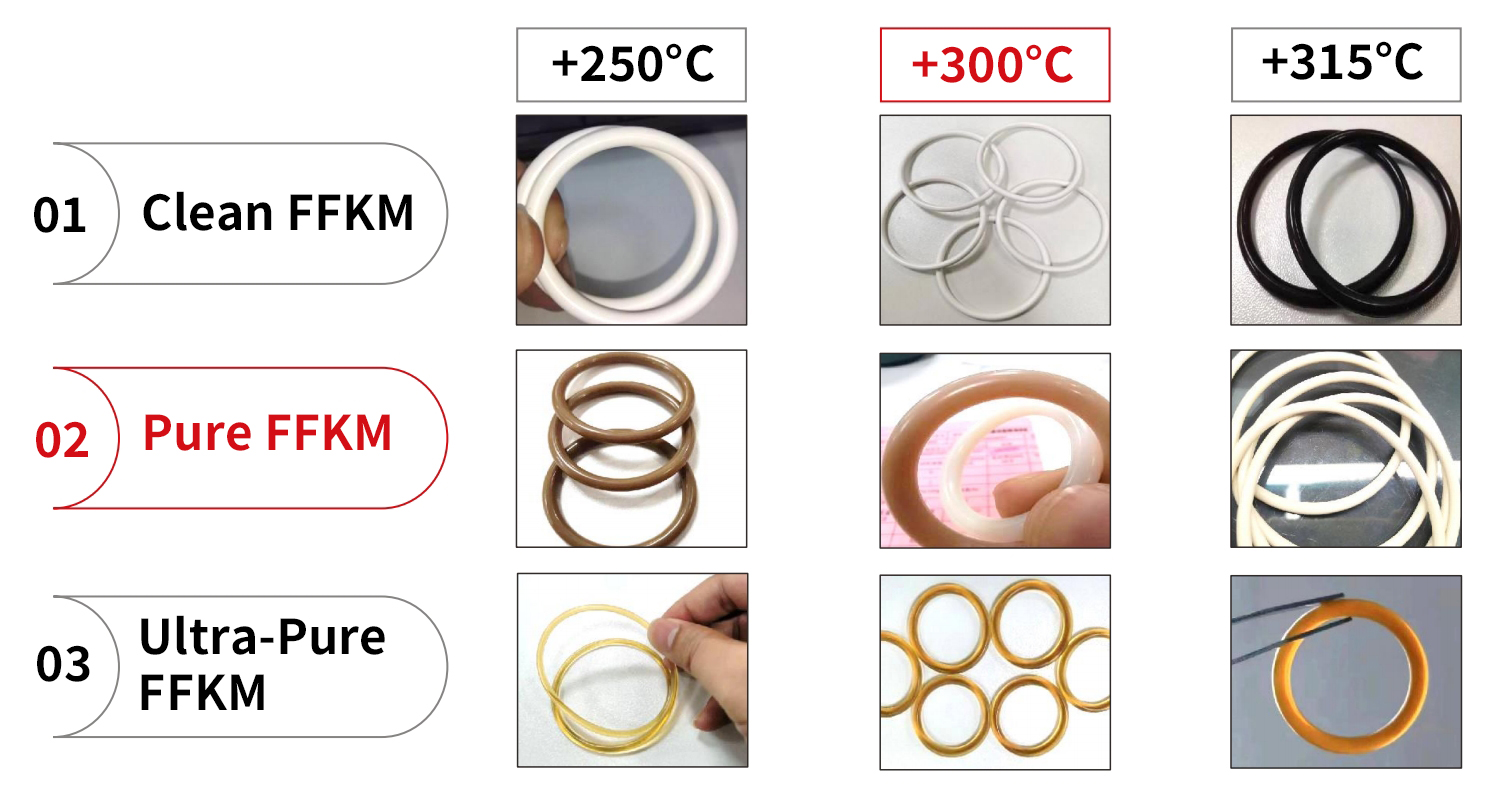

l FFKM: Extreme chemical and thermal resistance, often used in semiconductor, chemical processing, and high-purity applications.

Depending on the rubber type, X-rings can operate reliably between -60°C and +320°C. Correct material selection ensures the seal can withstand the operating environment without rapid degradation.

Hardness and Seal Longevity

Shore A hardness plays a critical role in X-ring durability. The hardness range typically spans 40–95 Shore A:

l Soft Compounds (40–60 Shore A): Provide excellent sealing against irregular surfaces but may wear faster in high-speed dynamic applications.

l Medium Hardness (70–80 Shore A): Balances wear resistance, sealing efficiency, and friction reduction; ideal for most dynamic applications.

l Hard Compounds (90–95 Shore A): Suitable for high-pressure environments; require precise groove design to prevent extrusion and ensure long-term reliability.

Selecting the proper hardness ensures the seal maintains contact under motion while minimizing wear and heat buildup.

Advantages of Metal Bonded Rubber X-Rings

Metal bonded X-rings are high-precision composite seals in which the rubber element is bonded to a metal insert. This combination delivers several benefits critical to extending seal life:

l Dimensional Stability: Maintains precise shape under high pressure, motion, and temperature changes.

l Enhanced Mechanical Strength: Metal inserts prevent deformation, allowing consistent sealing performance over time.

l Vibration Damping: Rubber absorbs shocks and vibrations between rigid metal interfaces, reducing mechanical stress on the seal and surrounding components.

l Strong Adhesion: Vulcanized or chemically bonded rubber prevents delamination, ensuring long-term durability.

These properties make metal bonded X-rings particularly effective in high-performance, high-stress industrial applications.

Industrial Applications

Rubber X-rings and metal bonded seals find extensive use in industries where dynamic sealing is critical:

l Automotive: Brake systems, shock absorbers, engine mounts, and hydraulic actuators rely on X-rings for vibration damping and leak-free performance.

l Industrial Machinery: Pumps, compressors, rotary shafts, and hydraulic cylinders require seals that resist wear under continuous motion.

l Oil & Gas: Pipelines and hydraulic systems depend on dynamic seals for high-pressure and fluctuating temperature environments.

l HVAC Systems: Compressors, fans, and moving valves benefit from reduced friction, stable sealing, and vibration isolation.

l Electronics and Semiconductor Equipment: Metal bonded X-rings provide contamination-free, high-purity sealing in sensitive environments.

In each of these applications, X-rings improve reliability, reduce maintenance frequency, and extend overall equipment life.

Design Considerations for Long Seal Life

To maximize the longevity of rubber X-rings in dynamic applications, several design factors must be considered:

l Groove Design: Proper groove depth and width prevent extrusion and ensure optimal squeeze.

l Surface Finish: Smooth mating surfaces reduce wear and friction.

l Lubrication: Appropriate lubricants reduce friction, wear, and heat buildup.

l Bonding Integrity: For metal bonded seals, strong adhesion prevents delamination during operation.

l Compliance and Certifications: Ensure the seals meet industry standards such as RoHS, REACH, FDA, and UL where required.

Custom shapes, thicknesses, and bonding designs can be tailored to specific machinery and operating conditions, ensuring long-lasting performance.

Testing and Validation

Testing is crucial for verifying seal performance in dynamic applications. Prototypes should undergo rigorous testing that simulates operational conditions, including:

l Rotary and reciprocating motion cycles

l Pressure variations and thermal cycling

l Vibration and shock loading

l Long-term wear and friction analysis

Validated designs minimize the risk of premature failure, ensuring seals perform reliably over their intended service life.

Working with Experienced Seal Manufacturers

Partnering with experienced seal manufacturers helps optimize material selection, bonding methods, and design parameters. Expert guidance ensures the seals meet the exact demands of dynamic applications, delivering long-term performance.

For high-quality rubber X-ring and metal bonded X-ring solutions, visit:

https://www.haosealtech.com/product/

Collaborating with trusted manufacturers ensures leak-proof, durable, and reliable sealing solutions for demanding industrial and automotive applications.

Conclusion

Rubber X-rings, particularly metal bonded designs, are a superior choice for dynamic sealing environments. Their multiple sealing surfaces, reduced friction, anti-roll geometry, and vibration damping properties provide extended seal life in rotary and reciprocating systems. Proper material selection, hardness, groove design, and bonding integrity are essential for achieving long-term durability and reliable performance across automotive, industrial, and high-precision applications. By implementing these advanced sealing solutions, engineers can significantly reduce maintenance, improve reliability, and ensure efficient operation in dynamic machinery.

https://www.haosealtech.com/product/

R&D