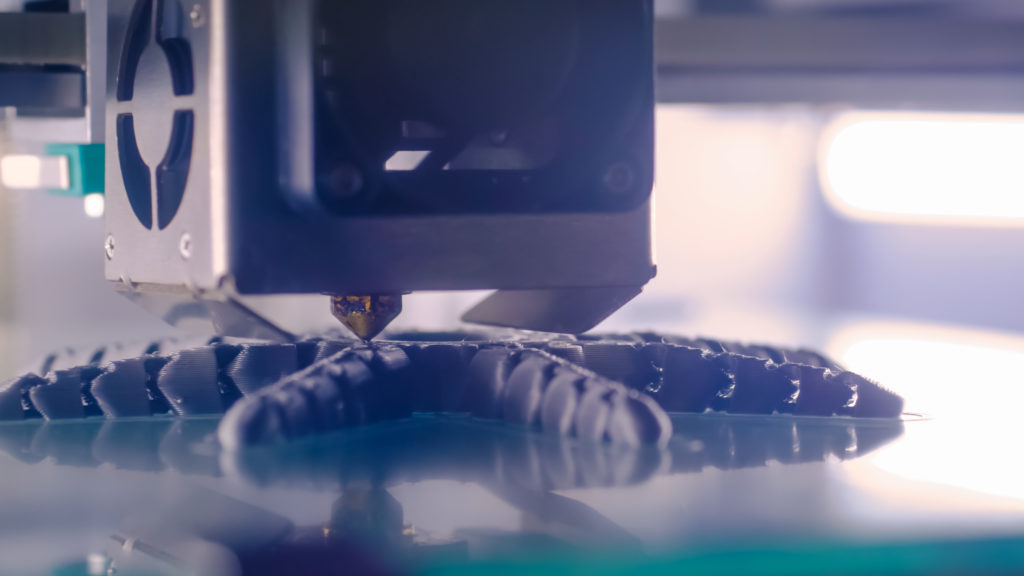

In recent years, 3D printing has revolutionized various industries, enabling the creation of complex and customized objects with ease. One crucial aspect of 3D printing is the choice of materials. With a wide range of options available, it can be challenging to determine which material is best suited for a specific application. In this article, we will delve into the world of 3D printing materials, exploring their characteristics, applications, and the factors to consider when selecting the ideal material for your 3D printing projects.

- PLA (Polylactic Acid):

PLA is one of the most popular materials used in 3D printing. Derived from renewable resources such as cornstarch or sugarcane, PLA is biodegradable and environmentally friendly. It offers excellent printability, low warping, and a wide range of vibrant colors. PLA is ideal for prototyping, educational purposes, and objects that do not require high mechanical strength. - ABS (Acrylonitrile Butadiene Styrene):

ABS is a durable and impact-resistant thermoplastic commonly used in 3D printing. It offers better mechanical properties than PLA, making it suitable for functional prototypes, automotive parts, and consumer products. However, ABS requires a heated print bed and proper ventilation due to the emission of potentially harmful fumes during printing. - PETG (Polyethylene Terephthalate Glycol):

PETG combines the best features of both PLA and ABS. It is strong, flexible, and exhibits excellent layer adhesion. PETG is resistant to moisture, chemicals, and UV radiation, making it suitable for outdoor applications, mechanical parts, and food containers. Additionally, it is relatively easy to print with and offers good transparency. - Nylon:

Nylon is a versatile material known for its high strength, durability, and flexibility. It is commonly used in industrial applications, such as aerospace and automotive industries, due to its excellent mechanical properties. Nylon requires specific printing conditions, including a heated chamber, to prevent warping. It is ideal for functional prototypes, gears, and parts subjected to high stress. - TPU (Thermoplastic Polyurethane):

TPU is a flexible filament that exhibits excellent elasticity and impact resistance. It is commonly used for producing wearable devices, phone cases, and flexible parts. TPU's ability to withstand repetitive bending and stretching makes it suitable for applications requiring flexibility and shock absorption. - Metal Filaments:

For those seeking to print metal objects, metal filaments offer a viable solution. These filaments consist of a mixture of metal powder and a binding agent. After printing, the object can be further processed to remove the binding agent and sinter the metal particles together, resulting in a solid metal object. Metal filaments are used in industries such as jewelry, engineering, and prototyping.

Conclusion:

Choosing the right material for 3D printing is crucial to achieve desired results. Each material has its unique properties and applications, and understanding these characteristics is essential for successful 3D printing projects. Whether you prioritize strength, flexibility, biodegradability, or specific industry requirements, there is a material available to meet your needs. By considering factors such as mechanical properties, printability, and intended application, you can make an informed decision and unlock the full potential of 3D printing technology.